Precision Timing Pulleys: High-Torque, Customizable Power Transmission Solutions

Discover our range of Precision Timing Pulleys, engineered for accurate synchronous power transmission demanding high torque and exceptional wear resistance. These robust toothed pulleys form the core of reliable drive systems. We offer extensive customization to meet your exact requirements. Choose from high-strength materials like 42CrMo alloy steel, carbon steel, stainless steel, aluminum alloy, or nylon. Enhance durability and performance with optional surface treatments including carburizing and quenching, hard chrome plating, Ferroferric Oxide Protective Film Treatment, nickel plating, or anodizing. Our pulleys intelligently adapt to over 20 international tooth profile standards, such as AT5/AT10, HTD (3M/5M/8M), STS (3M/5M/8M), and MXL/XL/L, ensuring seamless integration into your existing systems. Find your perfect precision transmission component here.

These versatile components are ideally suited for demanding applications in 3C Electronic Production Lines, CNC Machines, Logistics Warehousing Systems, and beyond. Find your perfect precision transmission component here.

Industrial Belt Manufacturer & Supplier Nantong Lanpeng Intelligent Machinery Co., Ltd.

Nantong Lanpeng Intelligent Machinery Co., Ltd. (LP Belt) is a high-quality transmission product manufacturer established in 2013. Headquartered in Nantong, China—a core manufacturing hub in the Yangtze River Delta. LP Belt specializes in the research, development, production, and global distribution of efficient and durable transmission solutions. Our products serve a variety of industries, including new energy, photovoltaics, logistics, machine tools, textiles, printing, packaging, healthcare, robotics and automation, and wood...

Read more

Our Products & Services

We deliver efficiency, durability, and precision across critical applications:

Timing Pulleys

Application Scenarios of Timing Pulleys

3C Electronic Production Line

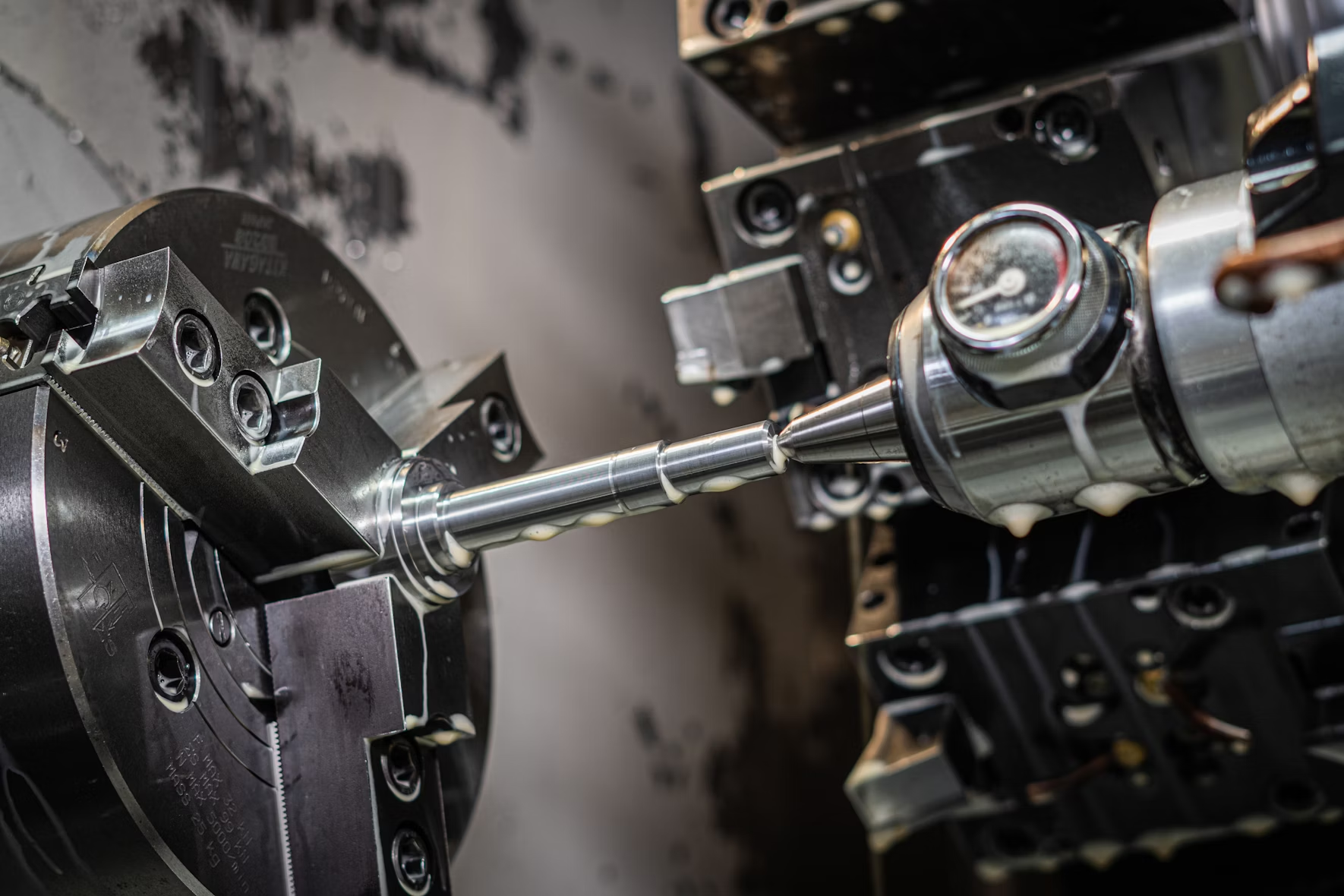

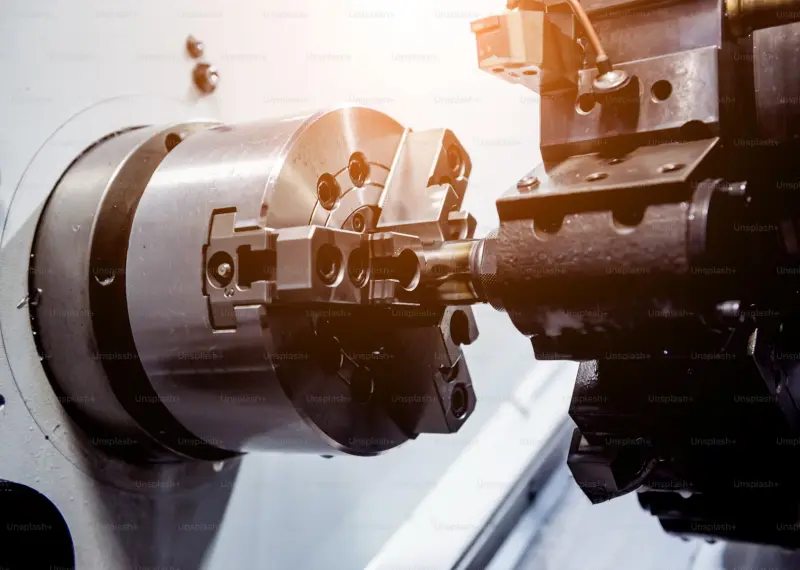

CNC Machine

Logistics Warehousing

Rubber Timing Belt

Precision Rubber Timing Belts: High-Load, Zero-Slip Drives

LP Rubber Timing Belts deliver reliable synchronous power transmission for high-load applications. Featuring glass fiber cords + nylon 66 tooth fabric, they ensure zero slippage, low noise, and extended life in automation, automotive, and packaging systems. Fully customizable with fast delivery.

Engineered to excel in diverse sectors including Industrial Automation, Medical Equipment Precision Transmission, Rail Transportation Equipment, and beyond.

Rubber Open Timing Belt: Cut-to-Length, On-Demand Solutions

LP Open-End Belts support free cutting to custom lengths, eliminating inventory costs and lead times. Built with glass fiber + nylon 66 teeth, they offer precision strength while boosting installation speed by 70% and reducing costs by 40%. Ideal for maintenance, retrofits, and prototyping.

Further extending their versatility, these belts are widely adopted in Laboratory Equipment, Packaging Machinery, Printing Machinery, and other precision-driven industries.

Rubber Double-Sided Synchronous Belt: Compact Bidirectional Power

LP Double-Sided Belts enable space-saving bidirectional drives in one belt. With glass fiber cores + dual nylon 66 teeth, they increase load capacity by 50% and minimize backlash for robotics, medical, and automation equipment. Customizable + fast delivery.

Tailored to thrive in Industrial Robots, Medical Equipment Precision Transmission, Packaging Machinery, and other high-precision sectors.

LP Rubber Timing Belts deliver reliable synchronous power transmission for high-load applications. Featuring glass fiber cords + nylon 66 tooth fabric, they ensure zero slippage, low noise, and extended life in automation, automotive, and packaging systems. Fully customizable with fast delivery.

Engineered to excel in diverse sectors including Industrial Automation, Medical Equipment Precision Transmission, Rail Transportation Equipment, and beyond.

Rubber Open Timing Belt: Cut-to-Length, On-Demand Solutions

LP Open-End Belts support free cutting to custom lengths, eliminating inventory costs and lead times. Built with glass fiber + nylon 66 teeth, they offer precision strength while boosting installation speed by 70% and reducing costs by 40%. Ideal for maintenance, retrofits, and prototyping.

Further extending their versatility, these belts are widely adopted in Laboratory Equipment, Packaging Machinery, Printing Machinery, and other precision-driven industries.

Rubber Double-Sided Synchronous Belt: Compact Bidirectional Power

LP Double-Sided Belts enable space-saving bidirectional drives in one belt. With glass fiber cores + dual nylon 66 teeth, they increase load capacity by 50% and minimize backlash for robotics, medical, and automation equipment. Customizable + fast delivery.

Tailored to thrive in Industrial Robots, Medical Equipment Precision Transmission, Packaging Machinery, and other high-precision sectors.

Application Scenarios of Rubber Timing Belt

Packaging Machinery

Printing and Packaging Machinery

Laboratory Equipment

Rail Transportation Equipment

Medical Equipment Precision ransmission

Industrial Robots

Multi-ribbed Belt

Multi-Ribbed Belts: High-Efficiency, Space-Optimized Power Transmission

Description: LP Multi-Ribbed Belts revolutionize drive systems by replacing outdated V-belts with an advanced multi-groove design. Engineered for high-torque applications, they solve critical industry pain points:

✅ Eliminate slippage and reduce spatial footprint by enabling single-belt multi-axis transmission

✅ Boost transmission efficiency by 25% and cut energy consumption by 15%

✅ Deliver ultra-low noise operation and extended service life

Technical Superiority: Constructed with high-tensile glass fiber cords and abrasion-resistant nylon 66 tooth fabric, these industrial-grade belts excel in demanding environments:

➤ Automotive systems (serpentine drives, alternators)

➤ High-speed machinery (pumps, compressors)

➤ Precision appliances (HVAC, power tools)

Customize rib patterns, lengths, and materials for seamless OEM integration. Super-fast global delivery ensures minimal downtime.

Description: LP Multi-Ribbed Belts revolutionize drive systems by replacing outdated V-belts with an advanced multi-groove design. Engineered for high-torque applications, they solve critical industry pain points:

✅ Eliminate slippage and reduce spatial footprint by enabling single-belt multi-axis transmission

✅ Boost transmission efficiency by 25% and cut energy consumption by 15%

✅ Deliver ultra-low noise operation and extended service life

Technical Superiority: Constructed with high-tensile glass fiber cords and abrasion-resistant nylon 66 tooth fabric, these industrial-grade belts excel in demanding environments:

➤ Automotive systems (serpentine drives, alternators)

➤ High-speed machinery (pumps, compressors)

➤ Precision appliances (HVAC, power tools)

Customize rib patterns, lengths, and materials for seamless OEM integration. Super-fast global delivery ensures minimal downtime.

Application Scenarios of Multi-ribbed Belt

Automobile Manufacturing

CNC Machine

Electric Vehicle Drive System

PU Timing Belt

Welded PU Timing Belts: Spliced Strength, Zero-Cut Customization

LP Connected PU Belts revolutionize long-length transmission with specialized welding technology that creates seamless, burr-free joints. Eliminating traditional cutting issues, they deliver 30% higher efficiency while preventing slippage and breakage. Engineered with oil-resistant, anti-aging polyurethane, these belts maintain precision in harsh environments. Ideal for custom-length installations requiring uninterrupted power transfer.

Proven performers in continuous-operation settings like Airport Baggage Sorting Lines, Mine Conveyor Systems, Textile Machinery, and beyond.

Open PU Belts: Rapid-Install Precision Drives

LP Open PU Belts combine trapezoidal/arc tooth profiles (≤0.1mm error) with German-engineered winding for ultra-precise motion control. Featuring reinforced polyurethane, they achieve 50% greater wear resistance and 15% energy savings through low-friction design. Oil-resistant and instantly customizable, they optimize maintenance in eco-sensitive production lines.

Their precision and eco-efficiency make them indispensable for Food Packaging Machinery, Laser Cutting Machines, Testing Instruments, and other applications where accuracy and sustainability converge.

Seamless PU Belts: Zero-Failure, One-Piece Performance

LP Seamless PU Belts leverage monolithic molding technology to eliminate joint weaknesses, boosting tensile uniformity by 40% and efficiency to 98%. These maintenance-free solutions offer food-grade/high-temp variants while preventing unexpected downtime. Perfect for mission-critical applications demanding silent, error-free transmission.

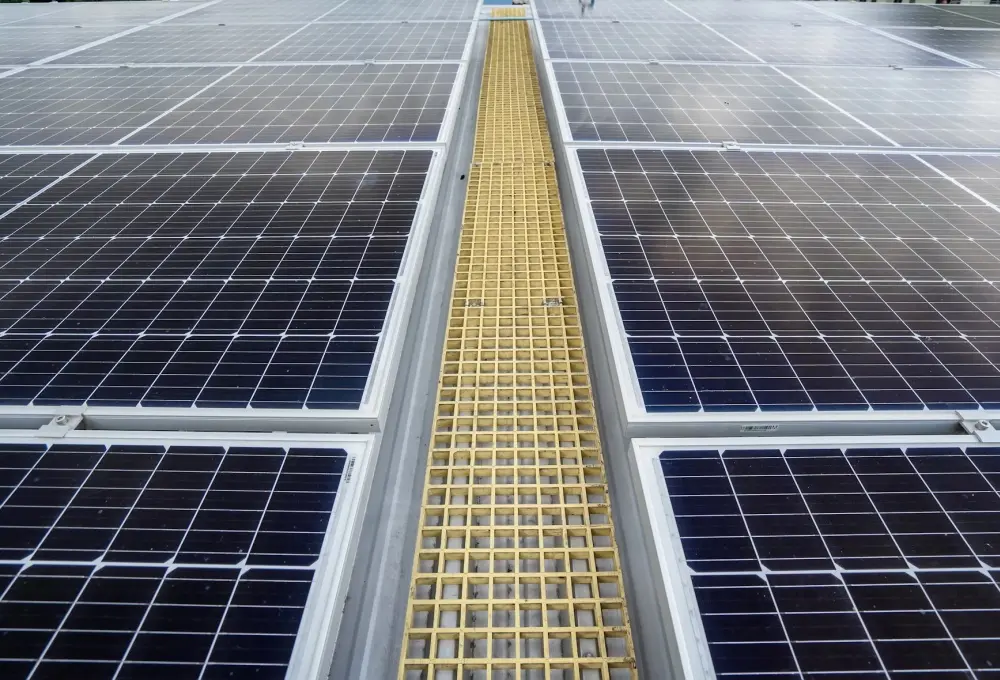

Specifically engineered for ultra-reliable operation in Baking Production Lines, MRI Machine Transmission Systems, Photovoltaic Panel Lamination Lines, and other zero-tolerance environments.

LP Connected PU Belts revolutionize long-length transmission with specialized welding technology that creates seamless, burr-free joints. Eliminating traditional cutting issues, they deliver 30% higher efficiency while preventing slippage and breakage. Engineered with oil-resistant, anti-aging polyurethane, these belts maintain precision in harsh environments. Ideal for custom-length installations requiring uninterrupted power transfer.

Proven performers in continuous-operation settings like Airport Baggage Sorting Lines, Mine Conveyor Systems, Textile Machinery, and beyond.

Open PU Belts: Rapid-Install Precision Drives

LP Open PU Belts combine trapezoidal/arc tooth profiles (≤0.1mm error) with German-engineered winding for ultra-precise motion control. Featuring reinforced polyurethane, they achieve 50% greater wear resistance and 15% energy savings through low-friction design. Oil-resistant and instantly customizable, they optimize maintenance in eco-sensitive production lines.

Their precision and eco-efficiency make them indispensable for Food Packaging Machinery, Laser Cutting Machines, Testing Instruments, and other applications where accuracy and sustainability converge.

Seamless PU Belts: Zero-Failure, One-Piece Performance

LP Seamless PU Belts leverage monolithic molding technology to eliminate joint weaknesses, boosting tensile uniformity by 40% and efficiency to 98%. These maintenance-free solutions offer food-grade/high-temp variants while preventing unexpected downtime. Perfect for mission-critical applications demanding silent, error-free transmission.

Specifically engineered for ultra-reliable operation in Baking Production Lines, MRI Machine Transmission Systems, Photovoltaic Panel Lamination Lines, and other zero-tolerance environments.

Application Scenarios of PU Timing Belt

Airport Baggage Sorting Lines

Mine Conveyor Belts

Textile Machinery

Food Packaging Machinery

Laser Cutting Machines

Testing Instruments

MRI Machine Transmission

Photovoltaic Panel Lamination Line

PU flat belt

Friction-Optimized PU Flat Belts: Zero-Contamination Precision Transmission

Description:

LP PU Flat Belts redefine material handling with engineered surface friction that ensures damage-free conveying and 98%+ transmission efficiency. Ideal for sensitive industries, they deliver:

✅ Zero material degradation – Seamless, non-marking contact surfaces

✅ Pollution-free operation – Non-lubricated design eliminates contamination risks

✅ Ultra-quiet performance – Noise levels <65 dB for precision environments

Technical Superiority:

Oil & hydrolysis-resistant polyurethane withstands harsh washdowns

Custom tooth structures (optional) enable high-torque/synchronous drives

Energy-saving profile reduces power loss by 15% vs. traditional belts

Custom widths, lengths, and compound formulations supported. OEM integration specialists standing by.

Description:

LP PU Flat Belts redefine material handling with engineered surface friction that ensures damage-free conveying and 98%+ transmission efficiency. Ideal for sensitive industries, they deliver:

✅ Zero material degradation – Seamless, non-marking contact surfaces

✅ Pollution-free operation – Non-lubricated design eliminates contamination risks

✅ Ultra-quiet performance – Noise levels <65 dB for precision environments

Technical Superiority:

Oil & hydrolysis-resistant polyurethane withstands harsh washdowns

Custom tooth structures (optional) enable high-torque/synchronous drives

Energy-saving profile reduces power loss by 15% vs. traditional belts

Custom widths, lengths, and compound formulations supported. OEM integration specialists standing by.

Application Scenarios of PU flat belt

AGV

Food Processing Line

Stereoscopic Warehouse Conveyor

PV Wafer Cassette Conveyor Assembly

Precision Wafer Conveyor Systems: Drift-Free, Cleanroom-Optimized Handling

Description:

LP PV Wafer Cassette Conveyor Assemblies eliminate critical bottlenecks in photovoltaic cell production. Engineered for nanometer-scale stability, they solve:

✅ Positioning drift (≤±0.1mm accuracy)

✅ Vibration-induced wafer damage (damped to ≤0.5G)

✅ Cleanliness loss (ISO Class 4 compatibility)

Core Innovations:

Active drift compensation via servo-guided rails

Anti-vibration monobloc frames with harmonic dampers

Sealed, non-outgassing materials (stainless steel 316L / PEEK)

Electrostatic discharge (ESD) control for wafer integrity

Customizable for 6″–12″ wafers. Validated in TOPCon, HJT, and perovskite lines.

Description:

LP PV Wafer Cassette Conveyor Assemblies eliminate critical bottlenecks in photovoltaic cell production. Engineered for nanometer-scale stability, they solve:

✅ Positioning drift (≤±0.1mm accuracy)

✅ Vibration-induced wafer damage (damped to ≤0.5G)

✅ Cleanliness loss (ISO Class 4 compatibility)

Core Innovations:

Active drift compensation via servo-guided rails

Anti-vibration monobloc frames with harmonic dampers

Sealed, non-outgassing materials (stainless steel 316L / PEEK)

Electrostatic discharge (ESD) control for wafer integrity

Customizable for 6″–12″ wafers. Validated in TOPCon, HJT, and perovskite lines.

Application Scenarios of PV Wafer Cassette Conveyor Assembly

Belt Conveyor

Belt Conveyor

Technical & Quality Excellence

Intelligent Manufacturing: Automated production + digital management for consistency.

ISO9001-Certified: Full-process quality traceability; rigorous wear/fatigue testing.

Innovation-Driven: 8% annual revenue invested in R&D for performance optimization.

Eco-Conscious: Low-energy processes + recyclable materials to reduce carbon footprint.

ISO9001-Certified: Full-process quality traceability; rigorous wear/fatigue testing.

Innovation-Driven: 8% annual revenue invested in R&D for performance optimization.

Eco-Conscious: Low-energy processes + recyclable materials to reduce carbon footprint.

Global Support & Speed

Pre-Sale: Rapid model selection + custom solutions from technical drawings.

On-Sale: 72-hour emergency delivery (if molds available); custom mold development.

After-Sale: 2-hour technical response.

On-Sale: 72-hour emergency delivery (if molds available); custom mold development.

After-Sale: 2-hour technical response.

Customer-Centric Values

24/7 global service hotline.

Customized solutions from demand analysis to delivery.

Partnerships across automotive, logistics, food machinery & Industry 4.0 sectors.

Customized solutions from demand analysis to delivery.

Partnerships across automotive, logistics, food machinery & Industry 4.0 sectors.

Our Vision & Mission

Vision:

Become the world’s leading belt drive manufacturer.

Mission:

Value Creation: Boost customer competitiveness via cost-effective products & rapid service.

Employee Growth: Foster talent through training, career development & fair incentives.

Sustainable Impact: Practice green manufacturing for a sustainable future.

FAQs

-

Q1: What industries do you serve?

Industries like new energy, photovoltaic, material handling, machine tools, textile, print, packaging, medical, robotics and automation, wood -

Q2: How do you ensure product quality?

-

Q3: Do you support custom requests?

-

Q4: What’s your lead time for urgent orders?

-

Q5: How do you handle technical issues?

Global Impact

Our products are trusted by partners worldwide, driving innovation in

transmission technology and enabling smarter, more efficient industries.

transmission technology and enabling smarter, more efficient industries.

Ready to Optimize Your Drive Systems?

[Contact Us Today] for Custom Solutions & Expert Support →