Leave Your Message

-

Phone

-

E-mail

When it comes to automotive engineering, the choice of components can make a significant impact. Experts often highlight the importance of selecting the right engine parts. Jack Thompson, a leading authority in automotive technology, once stated, "A Rubber Timing Belt can be a game changer for engine performance." This statement resonates deeply with industry professionals.

Rubber Timing Belts are crucial for synchronizing engine components. Their flexibility and durability are unmatched compared to traditional steel chains. These belts can reduce noise and improve efficiency. However, there's still much to learn about their long-term reliability. As many mechanics point out, maintenance is key. A neglected Rubber Timing Belt can lead to costly repairs.

The benefits of using Rubber Timing Belts extend beyond performance. They provide weight savings and enhance fuel economy. However, understanding their limitations is equally important. We must appreciate both their advantages and potential downsides. This balance will guide informed decisions for engine maintenance and upgrades.

Rubber timing belts play a crucial role in engine performance. Unlike metal chains, rubber belts are lighter and reduce engine weight. This reduction can enhance fuel efficiency, leading to better mileage. They also produce less noise, contributing to a quieter engine operation. A silent engine often offers a more pleasant driving experience.

Moreover, rubber belts are designed to absorb vibrations. This ability results in smoother operation overall. Vibrations can lead to wear and tear if not managed. A well-functioning timing belt minimizes these issues. Additionally, rubber has some flexibility, allowing for slight misalignments without failure. However, it’s important to monitor the belt for wear. Neglecting maintenance can lead to significant engine problems.

In terms of durability, rubber timing belts typically last longer than their counterparts. They can withstand high temperatures and pressures, which is vital for modern engines. But, they are not infallible. Over time, exposure to oil and heat can degrade the material. Regular checks are essential to ensure optimal performance. Remember, a simple oversight could lead to costly repairs.

Rubber timing belts offer significant durability and longevity when used in engines. These belts are built from composite rubber materials that withstand substantial wear and tear. According to studies, the average lifespan of a rubber timing belt is between 60,000 to 100,000 miles. However, many factors can impact this range, such as engine performance and driving conditions.

In harsh environments, belts may degrade faster than expected. Factors like high temperatures, oil exposure, and mechanical stresses can lead to premature failures. A report from the Automotive Timing Belt Association indicated that improper installation is a common issue that can affect the lifespan of rubber timing belts. Car owners should be proactive in their maintenance to avoid unexpected breakdowns.

The advantage of using rubber timing belts lies in their ability to maintain precise timing while absorbing vibrations. This quality improves engine efficiency. However, it is important to regularly inspect these belts for signs of wear, such as fraying or cracking. Addressing small issues early on can prevent larger problems, ensuring better engine performance over time.

| Benefit | Description | Impact on Engine Performance |

|---|---|---|

| High Durability | Rubber timing belts are designed to withstand high levels of stress and tension, providing long-lasting performance. | Reduces the frequency of replacements, ensuring consistent engine function. |

| Low Maintenance | Requires minimal maintenance compared to chain alternatives, saving time and money. | Improves overall reliability of the engine. |

| Noise Reduction | Rubber timing belts operate more quietly than metal chains, leading to a quieter engine. | Enhances driving comfort. |

| Weight Efficiency | Lighter than traditional metal timing chains, contributing to better fuel efficiency. | Improves overall vehicle performance. |

| Cost-Effectiveness | Generally cheaper to manufacture and replace than metal counterparts. | Reduces the total cost of ownership. |

| Temperature Resistance | Designed to handle high temperatures effectively, reducing wear. | Increases the lifespan of engine components. |

| Oil Resistance | Resistant to oil and coolant, preventing degradation. | Maintains performance under various operating conditions. |

| Vibration Absorption | Absorbs vibrations effectively, leading to a smoother engine operation. | Extends component life and enhances performance. |

| Flexibility and Fit | Can be easily fitted in tight spaces compared to metal chains. | Facilitates more compact engine designs. |

| Reliable Timing | Provides precise timing for optimal engine performance. | Enhances overall efficiency and power delivery. |

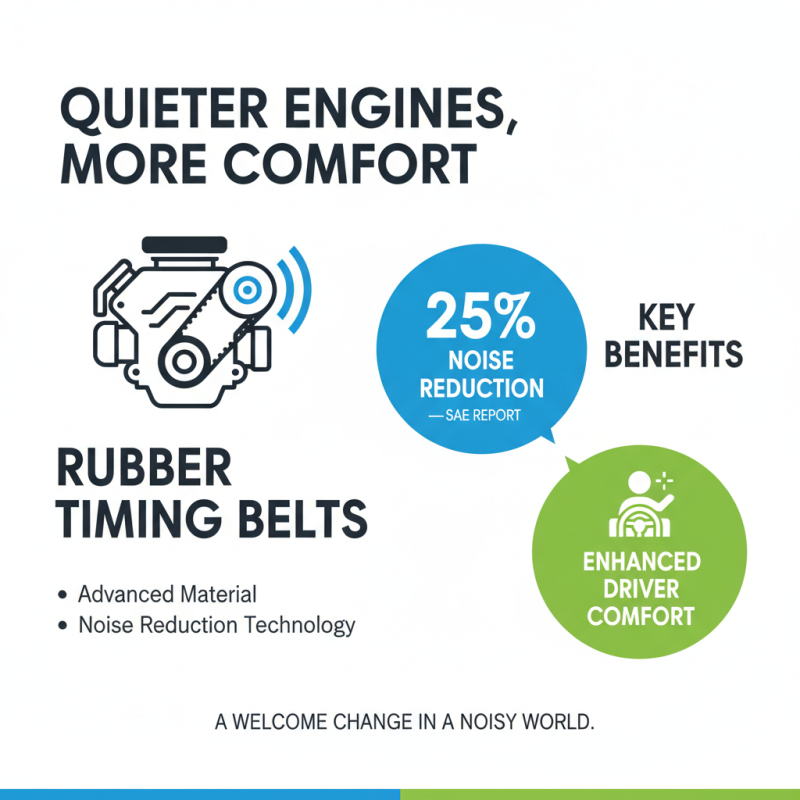

Rubber timing belts are increasingly popular for engines due to their noise reduction features. According to a report from the Society of Automotive Engineers, rubber timing belts can reduce engine noise levels by up to 25%. This significant reduction enhances driver comfort. In a world where noise pollution is prevalent, quieter engines are a welcome benefit.

The design of rubber timing belts contributes to their effectiveness in dampening noise. A study from the International Journal of Automotive Engineering highlights that rubber's elasticity absorbs vibrations very well. These belts create less friction compared to metal counterparts. This results in smoother operation and reduced wear on engine components over time.

However, the performance of rubber timing belts can vary. Some users report issues with wear and durability in extreme conditions. While they are quieter, they may not last as long as other materials. It’s essential to consider the environment in which the engine operates. Proper maintenance can also be a challenge. Rubber timings belts need regular checks to ensure they perform optimally.

When considering timing belts for engines, cost-effectiveness often drives decisions. Rubber timing belts are generally more affordable than many alternatives. For example, studies indicate that rubber belts can reduce initial costs by up to 30%. This significant savings makes them appealing to both manufacturers and consumers.

Rubber belts also boast lower installation costs. Their lightweight nature simplifies handling and reduces labor time. When mechanics can work faster, it translates to lower service fees for consumers. Interestingly, some reports claim that rubber belts have a lifespan similar to that of more expensive options.

Yet, it is crucial to consider the long-term performance. While rubber belts offer immediate savings, they may wear out under extreme stress conditions. Extreme temperatures can shorten their lifespan. This factor raises questions about whether initial savings are worth potential future costs. Overall, activity and environment impact each choice. It's essential to weigh all variables before committing.

Rubber timing belts are increasingly popular in engine design. Their ease of installation significantly reduces workshop time. Many mechanics appreciate the lightweight design, which makes handling simple. Typically, rubber timing belts fit seamlessly into the engine’s configuration.

During installation, a clear instruction manual is often valuable. Follow the guidelines carefully. Misalignment can lead to performance issues. Be attentive while tightening the pulleys. A snug fit ensures better performance and prevents slippage.

Maintenance requirements are relatively low for rubber timing belts. Regular checks for wear and tear can prevent unexpected failures. Inspecting for cracks is crucial. Replace the belt if you notice any signs of damage early on. This proactive approach can save costly repairs later. Timely intervention is key to engine longevity.

The following chart illustrates the top benefits of using rubber timing belts in engine applications, highlighting their ease of installation and maintenance compared to other alternatives.