Leave Your Message

-

Phone

-

E-mail

In the world of mechanical performance, chain sprockets are essential components that directly influence efficiency. Renowned expert in the field, John Smith, once said, “Choosing the right chain sprocket can make or break your machine’s performance.” This highlights the critical role chain sprockets play in various applications, from motorcycles to industrial machinery.

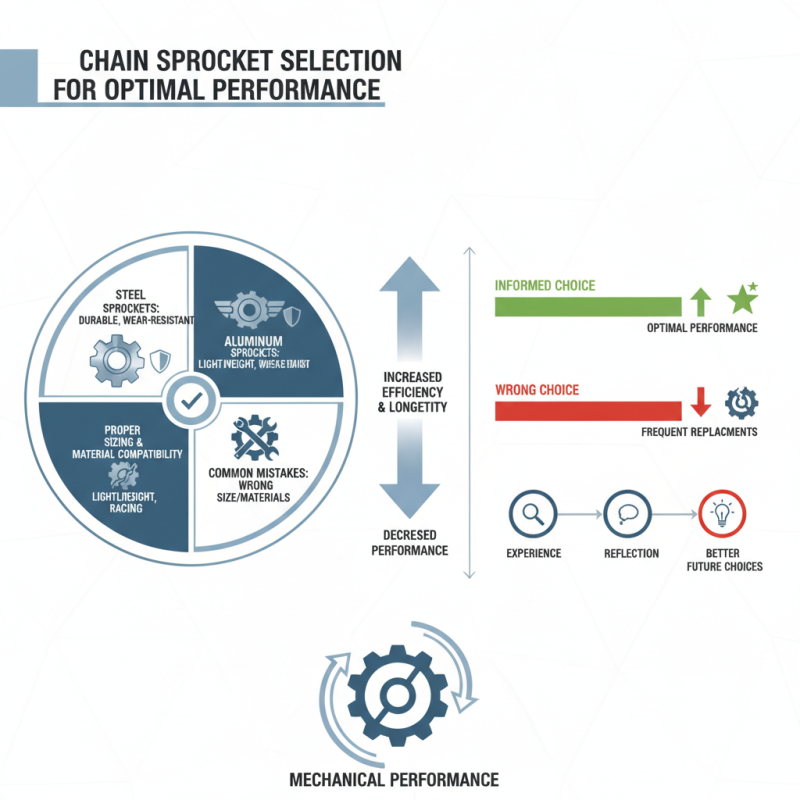

Different chain sprockets offer unique benefits. Steel sprockets are durable and wear-resistant, while aluminum ones are lightweight and ideal for racing. However, the choice isn’t always straightforward. Mistakes can occur, such as selecting the wrong size or using incompatible materials. Even small errors can lead to performance issues.

Investing time into understanding chain sprockets pays off. An informed decision can lead to better efficiency and longevity of your machinery. Be aware that the wrong choice might lead to frequent replacements and decreased performance. Reflecting on experiences can lead to better choices in the future.

Chain sprockets are crucial components in various machines. They connect the chain to the drivetrain, impacting efficiency and performance. A well-designed sprocket transfers power effectively. According to industry reports, the right sprocket choice can enhance performance by up to 25%. This can significantly affect overall machine productivity.

Sprockets come in different sizes and teeth configurations. Each variation influences speed and torque. For example, smaller sprockets can provide higher speeds but produce more wear. Conversely, larger sprockets may allow for better torque management but can limit speed. It's a balancing act that requires careful analysis. Studies suggest that proper alignment and wear monitoring are often overlooked. These factors can lead to premature failure.

Regular maintenance of sprockets is essential for optimal performance. Neglect can cause uneven wear and inefficiency. Interestingly, around 37% of equipment failures relate to drivetrain issues. Keeping an eye on wear patterns is vital. Owners must be conscious of the trade-offs between speed and durability in their sprocket choices. Each decision can lead to unintended consequences on machine performance.

| Rank | Sprocket Size (Teeth) | Material | Weight (grams) | Price (USD) | Performance Rating (1-10) |

|---|---|---|---|---|---|

| 1 | 15 | Aluminium | 250 | 25.99 | 9 |

| 2 | 20 | Steel | 300 | 18.50 | 8 |

| 3 | 25 | Carbon Steel | 350 | 30.00 | 9 |

| 4 | 30 | Aluminium | 270 | 28.75 | 7 |

| 5 | 35 | Steel | 400 | 20.99 | 8 |

| 6 | 40 | Carbon Steel | 450 | 32.50 | 9 |

| 7 | 45 | Aluminium | 380 | 22.30 | 8 |

| 8 | 50 | Steel | 480 | 35.75 | 10 |

| 9 | 55 | Carbon Steel | 500 | 27.99 | 9 |

| 10 | 60 | Aluminium | 500 | 40.00 | 10 |

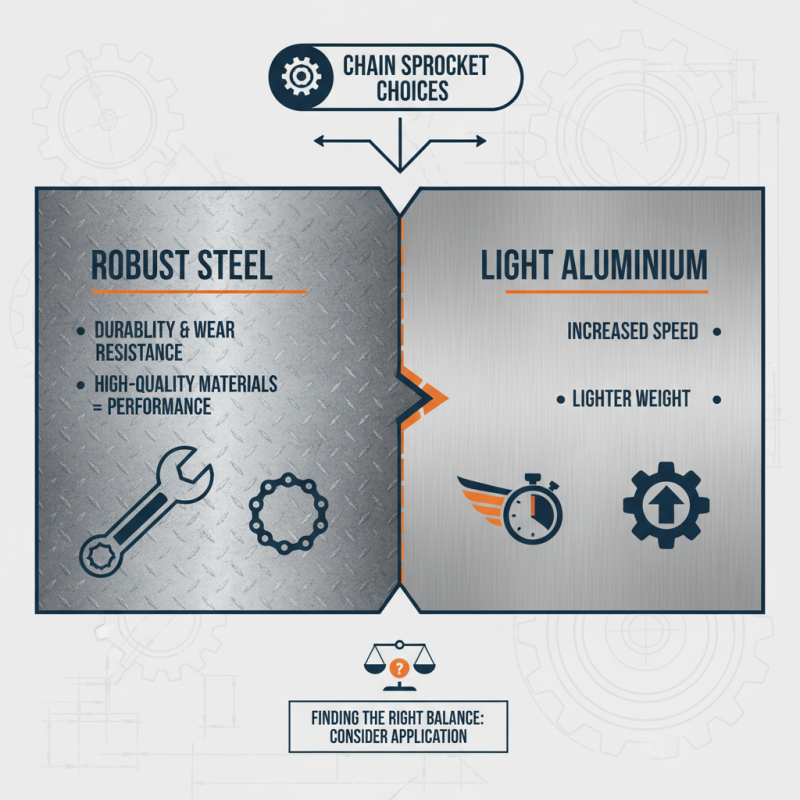

When selecting chain sprockets, several key factors come into play. First, consider the material used. Steel is common due to its strength, but aluminum is lighter. Each material has pros and cons. Steel can resist wear better, while aluminum allows for speed but may wear out faster.

The number of teeth is crucial too. More teeth mean increased torque and reduced speed. Fewer teeth result in faster speeds, but may sacrifice stability. It's essential to match sprocket size to your specific needs. Choosing the right size can make a significant difference in performance.

Another aspect is the pitch. The distance between chain links should correspond with the sprocket. Mismatched pitch can lead to uneven wear. Additionally, the design and finish of the sprockets impact their efficiency. Rough edges can cause drag and reduce overall effectiveness. Always examine these details carefully. Sometimes we overlook small aspects, but they can be pivotal.

When choosing chain sprockets, efficiency and durability are key. High-quality materials can significantly enhance performance. Robust steel options resist wear and tear, while lighter aluminum alternatives may improve speed. Each choice comes with trade-offs. Finding the right balance often requires careful consideration of the intended application.

Sprockets must also match the specific chain type. Mismatched components lead to poor performance and increased wear. Often, users overlook compatibility, which can result in frustration and costly repairs. Regular inspections can identify wear early and save time.

Investing in the right sprocket saves more than just money; it boosts overall efficiency. A well-maintained sprocket system operates smoothly, minimizing strain on the entire mechanism. Yet, users sometimes neglect routine maintenance. Without it, even the best sprockets can underperform.

When evaluating chain sprockets, material type plays a vital role. Steel, aluminum, and plastic are common choices, each with distinct benefits. Steel is durable and resistant to wear, but it adds weight. Aluminum is lighter and can enhance performance. However, it may wear out faster under heavy loads. Plastic sprockets are lightweight and inexpensive, but they might not last as long in high-stress environments.

The choice of material affects not just durability but also efficiency. Steel can handle greater torque, making it suitable for heavy machinery. In contrast, aluminum works well for bicycles and lightweight applications. Plastic can be beneficial in low-friction scenarios, but what about its heat resistance? Each material has trade-offs that need careful consideration.

Users often overlook the importance of proper maintenance. Even the best materials can degrade without care. Regular lubrication can extend the life of all types of sprockets. Choosing a material is one aspect, but maintaining it is another. It's crucial to find the right balance between performance and upkeep for optimal results.

Chain sprockets are essential for optimal performance in any machinery. To ensure they last, maintenance is crucial. Regular cleaning is not just helpful, it's necessary. Dirt and debris can cause wear on the sprocket teeth. A brush or a cloth can effectively remove this buildup. Ignoring this can lead to premature failure.

Lubrication plays a vital role too. Applying the right lubricant reduces friction and heat. However, too much can attract dust, reversing the benefits. Check your lubrication intervals and adjust based on usage. Sometimes, you might forget this step. A reminder can help keep your routine on track.

Inspecting the sprockets regularly is equally important. Look for any signs of wear or damage. Cracks or unusual wear patterns could indicate alignment issues. If you notice these, it’s time to reassess your setup. Maintaining optimal performance requires diligence. It is easy to overlook these small details, yet they significantly impact longevity.