Leave Your Message

-

Phone

-

E-mail

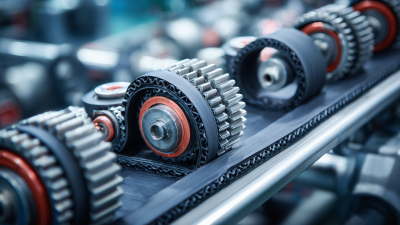

In the dynamic landscape of industrial manufacturing, the demand for effective and innovative Flat Belt solutions is on the rise. According to the latest market analysis by Global Industry Analysts, the global Flat Belt market is projected to reach USD 3.9 billion by 2025, driven by advancements in automation technologies and a surge in demand across various sectors such as automotive, food processing, and logistics. As industries evolve, the need for high-performance and durable belt systems has never been more critical.

Industry expert Dr. James Turner, a recognized authority on conveyor systems, emphasizes the significance of adaptability in this realm. He stated, "The future of Flat Belt technology lies in its ability to meet diverse operational challenges while maximizing efficiency." This highlights the ongoing trends towards customization and integration with smart technologies that are shaping the Flat Belt landscape. In this guide, we will explore the top picks and emerging trends in Flat Belt solutions for 2025, ensuring industries can stay ahead of the curve in their operational demands.

As the demand for efficient and versatile industrial solutions grows, flat belt technologies are evolving significantly. In 2025, the integration of emerging technologies such as IoT, AI, and advanced materials will redefine the landscape of flat belt systems. According to a recent market research report by Fortune Business Insights, the global flat belt market is projected to reach $4.2 billion by 2025, growing at a CAGR of 6.8%. This growth is largely driven by the increasing adoption of automation across various industries, including manufacturing, food processing, and logistics.

One of the most exciting advancements lies in the use of smart monitoring systems that leverage IoT. These systems enable real-time tracking of belt performance, allowing for predictive maintenance and reducing downtime significantly. For instance, belts equipped with sensors can communicate wear and tear, thus optimizing replacement schedules. Additionally, advancements in materials, such as reinforced polymers, are improving durability and efficiency, leading to longer service life and decreased energy consumption.

Tips: When selecting a flat belt solution, consider investing in smart technology that provides real-time data. This can lead to significant savings in maintenance costs and enhance overall operational efficiency. Moreover, choose belts made from advanced materials to benefit from better performance and sustainability. Engaging with suppliers who are at the forefront of these innovations can also provide customized solutions to meet specific industry needs.

The flat belt industry is projected to experience significant growth in 2025, driven by advancements in manufacturing processes and increased demand across various sectors. According to a recent report by Market Research Future, the global flat belt market is expected to reach approximately $7.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.3% from 2020. This upward trend can be attributed to the rising use of flat belts in automotive, food processing, and material handling sectors, which require reliable and efficient power transmission solutions.

Furthermore, the emphasis on sustainability and energy efficiency in industrial operations is pushing manufacturers to adopt innovative flat belt technologies. A report by Technavio highlighted that the integration of advanced materials, such as polyurethane and thermoplastic elastomers, is enhancing the durability and performance of flat belts. As companies prioritize reducing their carbon footprint, the demand for lightweight and longer-lasting belt solutions is set to rise, solidifying the flat belt's position as a critical component in modern machinery and equipment.

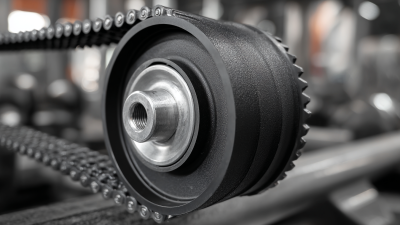

In the quest for enhanced durability and performance in various industries, flat belt solutions are evolving rapidly. As we approach 2025, the materials that form the backbone of these belts are being redefined. Key innovations include composite belts, which combine the strength of synthetic fibers with the flexibility needed for intricate machinery. These composites reduce wear and tear significantly, making them ideal for high-speed applications.

Another standout is the rise of polyurethane flat belts, valued for their exceptional resistance to abrasion and chemicals. This material not only extends the lifespan of the belts but also maintains optimal performance under challenging conditions. Additionally, the integration of advanced coatings is revolutionizing flat belt technology, providing superior grip and reducing slippage. The development of specific materials tailored for high-temperature environments promises to broaden the application scope, catering to industries ranging from manufacturing to food processing. These top materials are set to redefine the benchmarks of efficacy and longevity in flat belt solutions for years to come.

The emphasis on sustainability and efficiency is reshaping flat belt designs as we approach 2025. With increasing demands for eco-friendly manufacturing processes, the integration of sustainable materials is becoming a priority. Innovations are exploring the use of biodegradable plastics and recycled resources, which not only reduce waste but also lower the carbon footprint of production. In this context, the Plastics Industry Association's recognition of sustainable innovations serves as a catalyst for the industry to adopt greener practices.

Efficiency is another key trend driving the evolution of flat belts. As the power transmission belting market is projected to grow significantly, manufacturers are focusing on enhancing the performance of flat belts to meet the requirements of modern machinery. Advances in technology, such as the incorporation of smart features that monitor operational performance, reflect the industry's push toward maximizing efficiency.

These developments align with broader trends in various sectors, including renewable energy and innovative construction practices, which are all seeking more efficient and sustainable solutions for the challenges of the future.

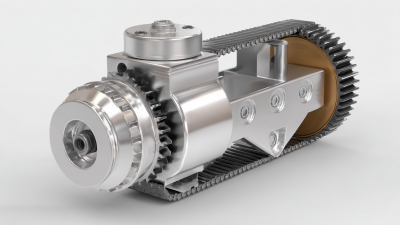

In the fast-evolving landscape of industrial automation, advanced flat belt systems have emerged as key players in enhancing operational efficiency. Notable case studies illustrate how companies across various sectors successfully implemented these technologies to streamline their production processes. For instance, a leading automotive manufacturer integrated a state-of-the-art flat belt conveyor system, optimizing space and reducing assembly line downtime. This not only improved their workflow but also significantly decreased the overall production time, showcasing the effectiveness of modern flat belt solutions.

In the food processing industry, a prominent organization adopted an innovative flat belt system designed for quick sanitation and easy maintenance. By incorporating a modular design approach, the company experienced fewer interruptions in their production line, leading to higher output. The ability to swiftly clean and reconfigure the belt system was pivotal in meeting strict hygiene regulations while also allowing for versatility in handling various products. These successful implementations highlight the adaptability and benefits of advanced flat belt systems, setting a benchmark for future trends in manufacturing and logistics.

| Application Area | Belt Type | Material | Key Features | Efficiency Improvement (%) | Successful Implementation Case |

|---|---|---|---|---|---|

| Automotive Manufacturing | Modular Flat Belt | Polyester | High load capacity, precise tracking | 15% | Increased production line speed |

| Food Processing | Heat-Resistant Belt | Nylon | High temperature tolerance, easy cleaning | 20% | Enhanced hygiene standards |

| Packaging Industry | Antistatic Belt | Polyurethane | Static electricity dissipation, durability | 25% | Reduced product damage during handling |

| Textile Manufacturing | Flexible Flat Belt | Polyester Fiber | Flexibility, resistance to wear | 18% | Increased material handling speed |

| Logistics and Distribution | Low Friction Belt | PVC | Minimal friction, smooth movement | 22% | Streamlined package sorting |