Leave Your Message

-

Phone

-

E-mail

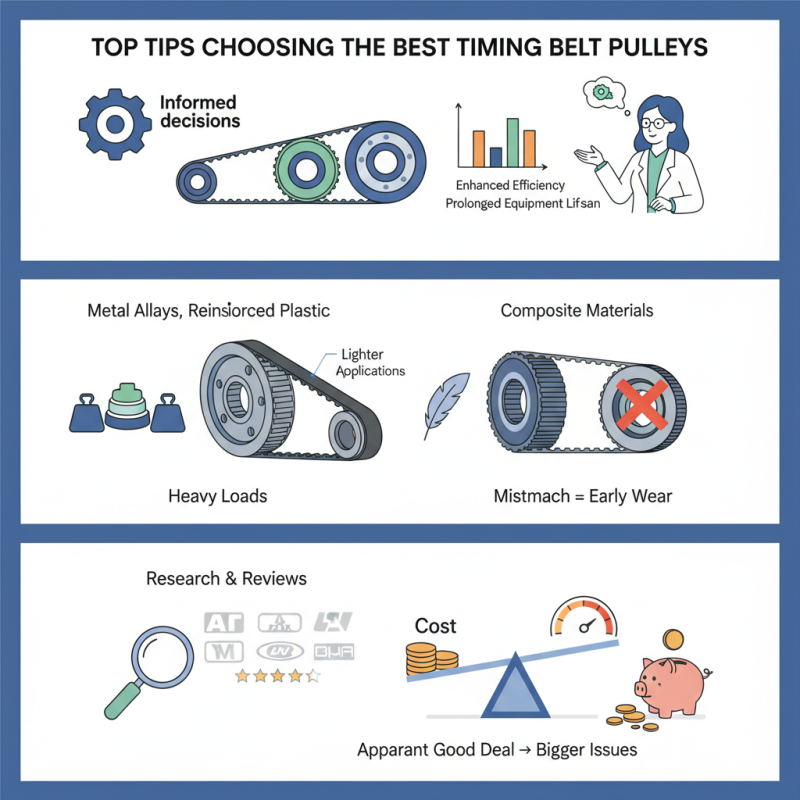

Choosing the right Timing Belt Pulleys is crucial for the performance of your machinery. Dr. Emily Carter, a renowned expert in mechanical engineering, once stated, “Proper pulleys can significantly enhance efficiency and prolong equipment lifespan.” This insight underscores the importance of making informed decisions when selecting Timing Belt Pulleys.

When considering your options, you should assess the material and design of the pulleys. Different applications may require specific characteristics. You might find that some pulleys are designed for heavy loads, while others are more suited for lighter applications. A mismatch can lead to early wear or failure.

Additionally, not every manufacturer provides the same quality. You might need to research brands and read reviews. Quality can vary significantly, and it’s essential to invest wisely. Remember, sometimes what appears to be a good deal may actually lead to more significant issues down the line. Balancing cost against performance is essential in this decision-making process.

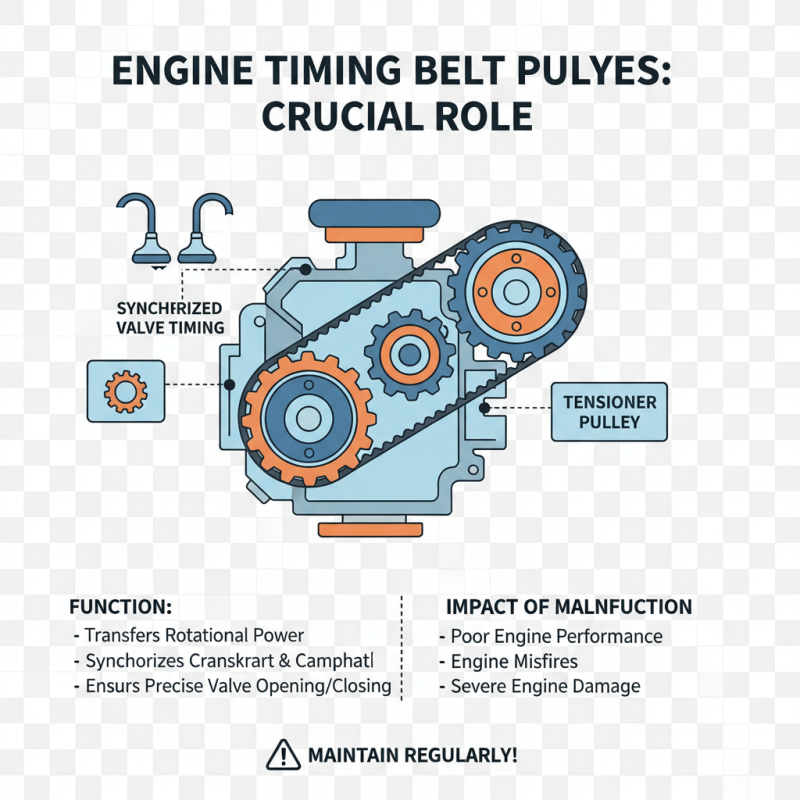

Timing belt pulleys play a crucial role in engine performance. They are responsible for transferring the rotational power between the crankshaft and camshaft. This synchronization ensures that the engine's valves open and close at the right moment. A malfunction can lead to serious engine issues.

Choosing the right timing belt pulleys is important. They come in different materials, sizes, and designs. Some people overlook these details. This can result in poor performance or even engine damage. Inspect the pulleys for wear and potential damage regularly. Consider how they interact with other components. Neglecting this can be costly down the line.

The right pulleys will optimize engine efficiency, making it run smoother. Pay attention to the specifications when buying. Not all pulleys fit every engine. Some might fit but not function properly. Research and ask questions. Your engine deserves the best to perform well.

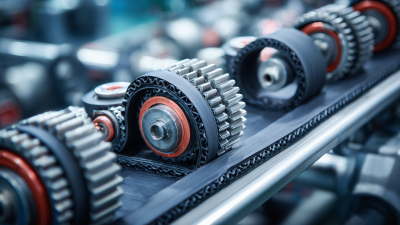

When selecting timing belt pulleys, understanding the materials involved is crucial. Common materials include aluminum, steel, and high-grade plastics. Aluminum is lightweight and resistant to corrosion, making it a popular choice for many applications. Steel offers strength and durability, perfect for heavy-duty tasks. High-grade plastics can be effective as well, often used in lower-stress environments.

The choice of material affects performance and longevity. Aluminum pulleys can wear out faster under certain conditions. Steel might be overkill for lighter applications. Plastics can sometimes degrade with heat and chemicals. It’s essential to reflect on your specific needs and the working environment of the pulley. Each material has its pros and cons. Making a wrong choice could lead to inefficiencies or premature wear.

Also, consider the manufacturing process of the pulleys. Machining, forging, or molding techniques all impact quality. Some methods are more precise, while others might not be as reliable. A poorly made pulley, regardless of the material, can lead to failure. Weighing these factors carefully can help in making a sound decision for your project.

Choosing timing belt pulleys requires careful consideration of several factors. One critical aspect is material selection. Pulleys made from high-strength alloys or reinforced plastics often outlast standard options. For instance, a study by the American Society of Mechanical Engineers found that pulleys made from advanced composites could offer up to 30% more durability.

Another vital element is the load capacity. It’s essential to align the pulley with the specific application. If the load exceeds the pulley’s design limits, it can lead to premature failure. Data from engineering research indicates that a mismatch in load rating can reduce efficiency by up to 25%.

The size and teeth configuration should not be overlooked. The number of teeth directly influences the belt's engagement and overall performance. A mismatch in sizes can cause significant wear, making it crucial to choose the correct specifications. Often, engineers overlook this detail, leading to costly downtime and repairs. Balancing these factors is challenging, but it is essential for operational success.

Choosing the right timing belt pulleys can be tricky. One common mistake is ignoring the size specifications. It's crucial to measure the belt size accurately before making a selection. A small miscalculation can lead to inefficient performance or even damage to your system. Always check the pitch diameter and tooth count.

Another mistake is overlooking the material quality. Some pulleys are made from cheaper materials that can't withstand high stress. This can lead to premature failure and increased costs over time. It's essential to choose durable materials that ensure longevity. Additionally, many forget to consider the environment in which the pulleys will operate. Exposure to harsh conditions can affect performance.

Lastly, many overlook compatibility with other components. If your pulleys don't work well with existing parts, you'll face issues later. Always do thorough research. Every detail matters. Don't be tempted to rush the decision. Taking time now will save headaches later.

Maintaining timing belt pulleys is crucial for vehicle performance. Reports show that over 30% of timing belt failures stem from improper maintenance. Regular inspections can identify wear and tear early. Examine the pulleys for cracks or signs of excessive wear. A quick check can save significant repair costs later.

Cleaning pulleys is often overlooked. Dirt and debris can accumulate, leading to inefficiency. Using a soft brush can help remove buildup. Additionally, lubricating the pulleys reduces friction. However, be cautious; over-lubrication can attract more dirt over time. Striking the right balance is essential for longevity.

Monitor alignment as well. Poorly aligned pulleys can strain the belt. This strain often leads to premature wear. Regularly check the alignment and adjust if necessary. Industry data indicates that nearly 20% of timing belt issues are due to misalignment. Taking these maintenance steps can enhance the lifespan of your timing belt pulleys significantly.