Leave Your Message

-

Phone

-

E-mail

Choosing the right Endless Flat Belt is crucial for optimal performance in various applications. These belts are commonly used in conveyor systems, manufacturing, and machinery. However, selecting the ideal belt can be challenging due to numerous options available in the market.

When considering an Endless Flat Belt, think about the specific requirements of your operation. Material type, width, and thickness are key factors that impact durability and efficiency. A belt that works well in one environment might not perform in another. Assessing your needs thoroughly ensures better results.

Keep in mind that even the most suitable Endless Flat Belt might require adjustments over time. Regular maintenance and monitoring help identify wear and potential issues early. This approach allows you to avoid costly downtimes. Ultimately, reflect on the balance between quality and cost, as the right choice can enhance overall productivity.

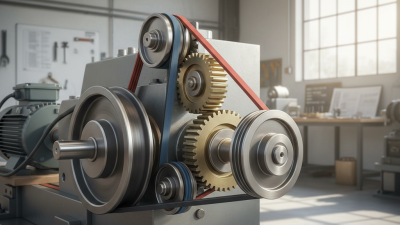

Endless flat belts are crucial in various industrial applications. They are designed to transport materials smoothly and efficiently. These belts are made from different materials, often tailored to specific needs. Understanding their features is essential for optimal choices.

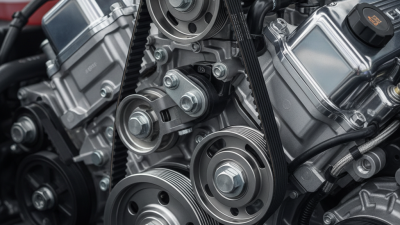

Applications range from manufacturing to logistics. In manufacturing, these belts often carry heavy loads. Consider a conveyor system in a warehouse. An endless flat belt can enhance productivity and reduce wear on machinery. However, a poor selection can lead to premature failure. Regular inspection and maintenance are vital for longevity.

Choosing the right belt involves assessing factors like load weight and speed. Each application may require unique specifications. It is important to analyze your needs carefully. Ignoring details can lead to costly mistakes. Take time to reflect on the specific environment of use. This will guide your decision-making process for better results.

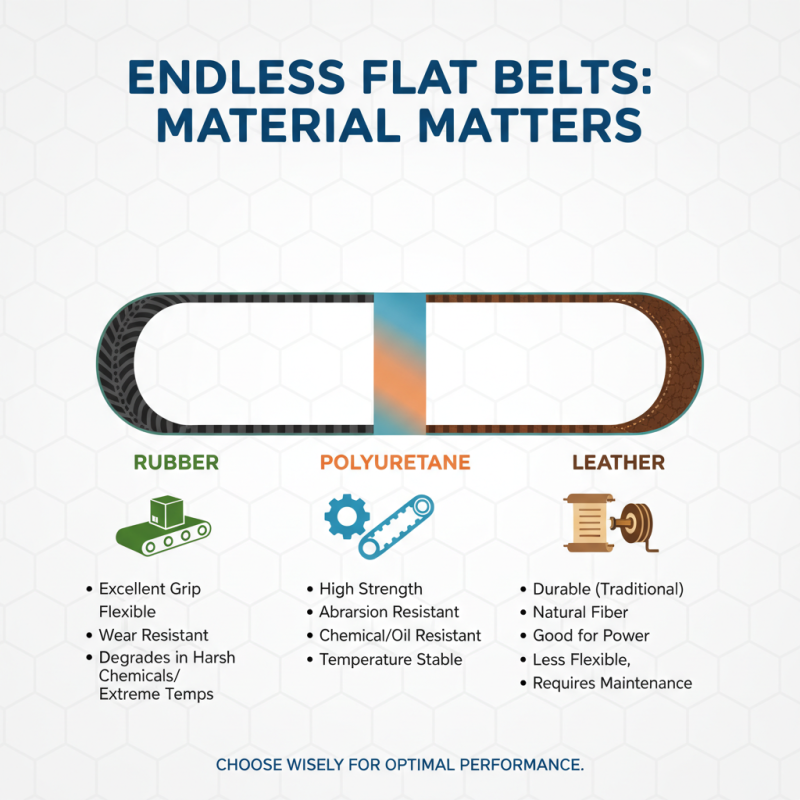

When choosing endless flat belts for various applications, key factors play a crucial role. Material type matters. Common options include rubber, polyurethane, and leather. Each has unique properties affecting flexibility and durability. For instance, rubber belts are widely used for their excellent grip but might degrade faster in harsh conditions.

Width and thickness are also important. A wider belt can distribute load more evenly. However, larger belts might be less flexible. According to industry reports, a belt's width can impact performance by up to 30%. Tip: Match the belt size to your application needs for optimal efficiency.

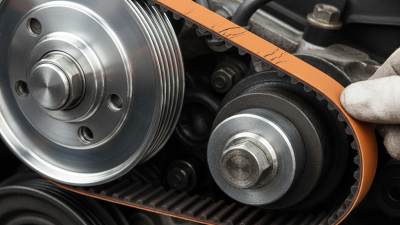

Consider operating conditions as well. Temperature variations, humidity levels, and exposure to chemicals can reduce belt lifespan. If your environment is demanding, selecting resilient materials is a must. Don't overlook tension and alignment either. Improper tension can lead to premature wear, while misalignment can cause significant failures. Tip: Regular maintenance checks can prevent costly downtimes and ensure longevity.

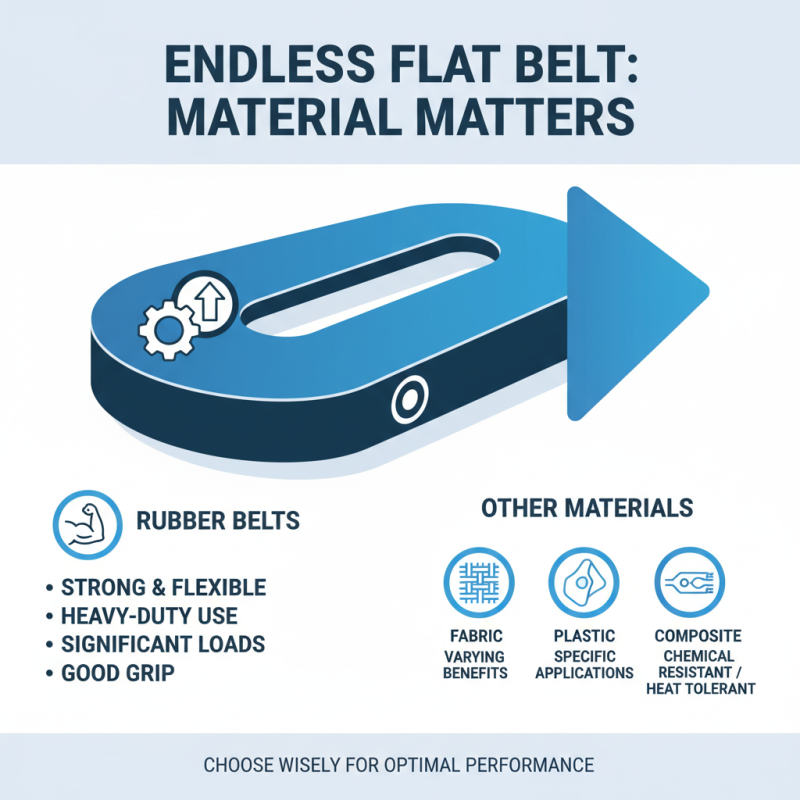

When choosing the right endless flat belt, material is key. Different materials offer various benefits based on your application. For instance, rubber belts are strong and flexible, making them ideal for heavy-duty use. They can handle significant loads while providing good grip.

On the other hand, thermoplastic materials are lighter and more resistant to chemicals and heat. If your application involves extreme temperature or exposure to solvents, consider these options. However, they may not provide the same load capacity as rubber belts. Each choice brings its advantages and limitations.

It’s important to evaluate your specific needs. This includes load requirements, the environment, and the belt's longevity. Sometimes, trial and error may be necessary. You could find that a material you thought was perfect doesn’t perform as expected. Reflecting on performance can guide future choices.

Choosing the right endless flat belt involves evaluating specific performance requirements.

Factors such as load capacity, speed, and environmental conditions play critical roles.

Industry data suggests that belts must be able to handle 20% more load than the maximum expected. This ensures safety and longevity.

Tips: Always check the belt's material composition. Different materials react differently under stress.

For instance, rubber belts are suitable for standard applications, while polyurethane options excel in tough environments.

Speed also affects belt life. Research indicates that over 60% of belt failures stem from speed-related issues.

Misalignment and incorrect tension worsen these problems. Regular inspection can mitigate risks.

Tips: Use tension measurement tools regularly. Maintaining proper tension enhances performance and reduces wear.

Environmental conditions must be taken into account. Factors such as temperature and exposure to chemicals can drastically alter performance.

Data show that belts used in harsher conditions may require frequent replacements.

Tips: Monitor the working environment regularly. Adjust your choice of belt based on changing conditions to prolong service life.

Endless flat belts are essential in many applications. To ensure optimal performance, regular maintenance is crucial. Inspecting the belt frequently can help. Look for signs of wear, such as fraying or cracking. These issues can lead to failures. A simple visual check can prevent more significant problems later.

When it comes to replacing endless flat belts, timing is everything. Replace them before they break. A sudden failure can halt operations. Understanding the lifespan of your belt is vital. Factors like load and speed will affect how long it lasts. Not replacing them in time can lead to costly downtimes.

Cleaning the belts regularly helps maintain their efficiency. Dirt and debris can cause slippage. This not only affects performance but also increases wear and tear. It's vital to take care of the small things. Neglecting these can lead to major issues down the line. Remember, small maintenance efforts lead to longer-lasting belts.

| Dimension | Material | Load Capacity (lbs) | Belt Width (inches) | Service Temperature (°F) | Lifespan (hours) |

|---|---|---|---|---|---|

| 1/2" x 25' | Polyester | 400 | 1.5 | -20 to 180 | 8000 |

| 3/4" x 30' | Nylon | 600 | 2.0 | -10 to 200 | 9000 |

| 1" x 40' | Rubber | 800 | 2.5 | 0 to 250 | 10000 |

| 1.5" x 50' | PVC | 1000 | 3.0 | -20 to 230 | 12000 |