Leave Your Message

-

Phone

-

E-mail

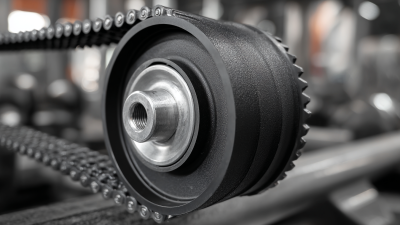

Drive pulleys play a crucial role in power transmission systems across various industries. These components ensure efficient energy transfer between rotating shafts. According to a report by Grand View Research, the global pulley market is projected to grow significantly in the coming years. This growth highlights the increasing demand for drive pulleys in various applications, including manufacturing, automotive, and material handling.

Drive pulleys enhance system reliability and performance. They help to minimize energy losses during mechanical operations. A study by the American Society of Mechanical Engineers indicates that proper use of drive pulleys can improve energy efficiency by up to 30%. However, not all systems utilize these components effectively. Many industries still struggle with outdated practices, leading to reduced performance and increased operational costs.

Incorporating advanced drive pulley designs can mitigate these issues. Innovations in materials and engineering are key. Yet, there remains a gap in awareness regarding optimal pulley applications. As industries evolve, understanding the importance of drive pulleys will be critical to enhancing operational efficiency. This discussion explores the essential role of drive pulleys in modern power transmission systems.

Drive pulleys play a crucial role in power transmission systems. They serve as the connection point between the engine and the machinery. Pulleys can effectively transfer torque and maintain proper speed. This ensures that machines operate smooth and efficiently. When the right pulley is chosen, energy loss can be minimized.

The materials and design of a drive pulley contribute to its performance. Often, pulleys must withstand heavy loads and harsh conditions. This raises questions about durability and maintenance. Some pulleys wear out faster under stress, leading to costly repairs. It's important to assess their condition regularly.

Understanding the proper alignment and installation is also vital. Misalignment can cause vibrations and decreased efficiency. Improperly installed pulleys can increase wear and lead to failure. Regular checks can help prevent these issues. Ideally, operators should be aware of these factors to ensure optimal performance.

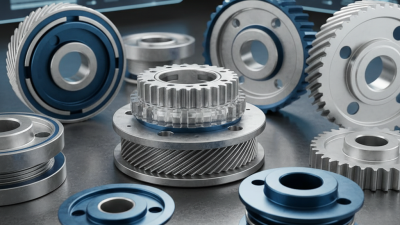

Drive pulleys are pivotal in power transmission systems. They come in various types, each designed for specific applications. For example, flat drive pulleys are commonly used in conveyor systems, providing a smooth surface for belts to glide over. These pulleys contribute to a significant 10% increase in efficiency compared to other pulley types, according to industry studies.

Another common type is the V-belt pulley. This design allows for better grip and higher RPMs, making it perfect for automotive applications. Recent reports indicate that V-belt systems can enhance torque by nearly 15%, demonstrating their effectiveness in heavy machinery. However, these systems may require frequent maintenance to maintain optimal performance.

Timing pulleys, also known as synchronous pulleys, feature teeth that mesh with a belt to ensure precise motion control. This precision is crucial in applications like robotics and CNC machines. However, the downside is their sensitivity to misalignment. Even minor deviations can result in wear and tear, impacting efficiency. Understanding the nuances of each type of pulley can lead to better choices in system design and implementation.

| Type of Drive Pulley | Material | Typical Applications | Advantages |

|---|---|---|---|

| V-Belt Pulley | Cast Iron | Agricultural Equipment, Conveyor Systems | High efficiency, low cost, easy maintenance |

| Chain Pulley | Steel | Motorcycles, Industrial Machinery | Durable, high torque transmission |

| Timing Pulley | Polyurethane | Robotics, Automotive | Precise timing, minimal slippage |

| Flat Belt Pulley | Aluminum | HVAC Systems, Textile Machines | Lightweight, good heat resistance |

| Idler Pulley | Plastic | Belt Conveyors, Large Scale Machines | Reduces belt tension and wear |

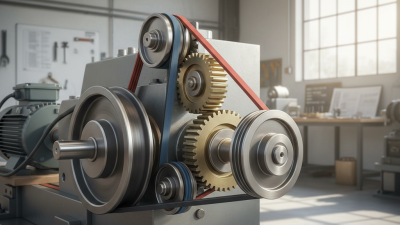

Drive pulleys play a vital role in enhancing efficiency within mechanical systems. By transferring power between rotating shafts, they help minimize energy loss. Data from industry studies reveal that effective pulley systems can improve efficiency by up to 30%. This is significant in industrial applications, where energy costs are a major concern.

Pulleys reduce friction and wear in mechanical systems. They guide belts and ropes smoothly, facilitating energy transfer. In fact, according to recent reports, improper pulley alignment can result in as much as 25% energy loss. Regular maintenance, however, can mitigate this issue. The importance of periodic checks can’t be overstated.

Implementing high-quality materials in drive pulleys can lead to enhanced durability. This means fewer replacements and lower operational costs. Researchers found that certain materials can extend lifespan by 40% compared to conventional options. However, choosing the right material remains a challenge. Not all systems benefit equally from advanced materials, prompting continuous evaluation and adjustment.

Drive pulleys play a crucial role in power transmission systems. Their performance is influenced by various key factors. Understanding these factors can lead to more efficient operations.

One primary aspect is the material used in pulley construction. High-grade materials can enhance durability. However, low-quality materials may cause premature wear. It’s essential to evaluate the material selection carefully. Another factor is the design of the pulley itself. The shape and size directly affect how power is transmitted. Misalignment can lead to inefficiencies and damage.

Belt tension is yet another critical element. Proper tension ensures that the pulley operates smoothly. Too much tension can strain components, while too little may result in slippage. Regular inspections are necessary to maintain balance. Lastly, environmental conditions also matter. Dust, moisture, and temperature can impact performance. Understanding these factors allows for improved maintenance strategies.

This bar chart illustrates various key factors that influence the performance of drive pulleys in power transmission systems, highlighting their respective performance ratings.

Drive pulleys play a vital role in ensuring efficient power transmission in various machinery. Regular maintenance is crucial for optimal performance. Small issues can escalate if not addressed promptly. Keep an eye on belt alignment and tension. Misalignment can cause wear and tear over time.

Tips: Check the pulley for any signs of damage. Listen for unusual sounds while operating. This may indicate a problem that requires immediate attention.

Cleaning the drive pulleys is often overlooked. Dust and debris can hinder performance. Use a soft cloth to wipe down the surface. Ensure all components are free from obstruction. Inspect bearings for smooth rotation. A squeaky pulley might signal that they need lubrication.

Tips: Lubricate according to the manufacturer's guidelines. Too much grease can attract dirt, worsening the issue. Testing the system periodically helps identify potential failures. Consider keeping a maintenance log to track performance over time. This can spotlight recurring problems that need deeper analysis.