Leave Your Message

-

Phone

-

E-mail

Drive belts are crucial components in numerous machines, from automobiles to industrial applications. Research shows that improper maintenance can lead to costly downtime. Approximately 30% of equipment failures are attributed to belt issues. Regular inspections and timely replacements can mitigate these risks.

Although many may overlook drive belts, they play an essential role in power transmission. Neglecting them can lead to significant performance declines. For example, a worn-out drive belt can reduce engine performance by up to 25%. This emphasizes the importance of understanding how to maintain them effectively.

In addition to routine checks, the right tension is vital. Over-tensioning or under-tensioning can cause premature wear and tear. Striking the right balance is not always straightforward, and the consequences of a mishap can be detrimental. Thus, using these ten essential tips will help extend the lifespan of your drive belts and improve overall efficiency.

Drive belts play a crucial role in vehicle operations. They transfer power between various components, ensuring everything runs smoothly. Without a functioning drive belt, your vehicle could face severe performance issues. Regular maintenance keeps these key components in good shape.

One effective tip is to check for wear and tear. Look for cracks or fraying on the belt. If you spot any damage, it may be time to replace it. This simple step can prevent further complications. Another important aspect is proper tension. A belt that is too loose can slip, while one that is too tight can cause premature wear. Adjusting the tension ensures efficient power transfer.

Don’t forget to keep belts clean. Dust and debris can lead to slippage and reduced efficiency. Regularly wipe the belts and inspect your pulleys too. Neglecting cleanliness might result in unexpected breakdowns. Remember that maintaining drive belts is an ongoing task. Reflect on your routine. Are you being thorough enough?

| Tip Number | Maintenance Tip | Importance | Frequency |

|---|---|---|---|

| 1 | Inspect for Wear and Tear | Prevents sudden failure | Monthly |

| 2 | Check Belt Tension | Ensures optimal performance | Monthly |

| 3 | Clean the Pulleys | Enhances grip and operation | Every 3 months |

| 4 | Check for Misalignment | Prevents excessive wear | Every 6 months |

| 5 | Listen for Unusual Noises | Identifies potential issues | Ongoing |

| 6 | Replace Worn Belts Promptly | Avoids breakdowns | As needed |

| 7 | Use Proper Lubrication | Reduces friction and wear | Annually |

| 8 | Monitor Operating Temperatures | Ensures efficiency | Monthly |

| 9 | Review Manufacturer Guidelines | Follows best practices | Annually |

| 10 | Consult a Professional if Needed | Ensures safety and reliability | As needed |

When it comes to drive belts in vehicles, understanding the different types is crucial. Belts generally fall into three major categories: serpentine belts, timing belts, and V-belts. Serpentine belts are long and flat, driving multiple components. They are commonly found in modern vehicles. Timing belts, however, play a vital role in synchronizing the engine's crankshaft and camshaft. V-belts are less common today but still found in older models. Each type serves distinct functions.

Maintaining these belts is essential for vehicle performance. Check belts regularly for wear or cracks. An old or worn belt can cause engine problems. Check tension regularly, too. A loose belt can slip and cause poor performance. If you hear strange noises, it may be time for a replacement.

Ignoring these signs can lead to bigger issues down the line. Invest time in maintenance. It saves money. To prolong belt life, ensure components they drive are functioning properly. A misaligned part can wear the belt prematurely. Take a moment to observe. If something seems off with the belts or the engine, don’t ignore it. A proactive approach prevents larger repairs later.

Drive belts are critical components in many machines. They transfer power from the engine to various parts. Understanding the signs of wear and tear can save time and money in repairs.

One common indicator of a worn drive belt is cracking. As belts age, they may develop small, shallow cracks on the surface. These cracks can expand over time, leading to potential breakage. A report by the American Society of Mechanical Engineers indicates that up to 40% of belt failures occur due to such surface issues.

Another sign to watch for is fraying. When the edges of the belt begin to fray, it shows that the belt is nearing the end of its life. This is more than just an aesthetic issue; fraying can affect performance and lead to slippage. In a survey conducted by the International Society of Automotive Engineers, 25% of respondents reported that they had experienced slippage due to worn belts. Finally, listen for unusual noises. Squeaking or squealing sounds may suggest that the belt is failing. Regular checks and awareness can help avoid costly breakdowns.

Drive belts play a vital role in the function of machinery. Regular inspection is crucial. According to a report by the Machinery Maintenance Association, nearly 30% of mechanical failures arise from improper belt maintenance. Ignoring these belts can lead to costly downtime and repairs.

Inspecting drive belts should occur monthly. Look for signs of wear, such as fraying or cracking. The belt should feel tight to the touch. If it seems loose, it may require adjustment. A study by the Industrial Belt Council revealed that 40% of belt-related issues stem from improper tension. This highlights the importance of checking tension levels regularly.

Routine maintenance can significantly extend belt life. Cleaning drive belts from debris reduces friction. Lubrication should be avoided, as this can attract dirt. It's worth noting that not all users maintain belts properly. Poor maintenance practices can negate the benefits of regular inspections. Environment impacts belt wear too; extreme temperatures can cause belts to degrade faster. Being conscious of these details can help in keeping belts functioning well.

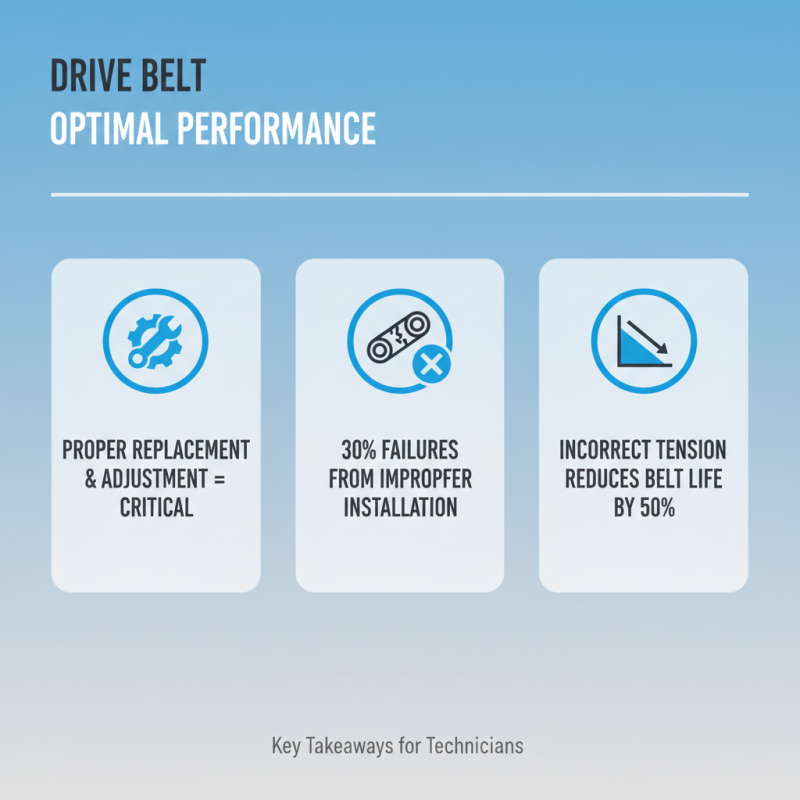

When it comes to drive belts, proper replacement and adjustment are critical in maintaining optimal performance. According to industry research, nearly 30% of drive belt failures stem from improper installation. Many technicians overlook alignment issues during installation, which can lead to premature wear. Ensuring correct tensioning is also vital. Studies indicate that incorrect tension can reduce belt lifespan by up to 50%.

Regular visual inspections can aid in early detection of wear signs. Look for cracks, fraying, or glazing on the belt surface. These issues can indicate a need for replacement. Using a tension gauge can help in adjusting the belt correctly. A well-adjusted belt should have a deflection of about 0.5 to 1 inch when pressed. Failure to adhere to this can lead to slippage or excessive strain on other components.

Being aware of environmental factors is also essential. High temperatures and exposure to oil can deteriorate belt integrity. It's advisable to replace belts at regular intervals, as waiting for visible signs of failure can be risky. Data shows that routine maintenance can extend your drive belts’ effective life up to 40%. Reflecting on your practices can reveal areas for improvement and enhance overall system reliability.