Leave Your Message

-

Phone

-

E-mail

Choosing the right chain sprockets for your vehicle can significantly impact performance, efficiency, and longevity. Research indicates that optimal sprocket selection can improve power transmission efficiency by up to 5%, a remarkable gain considering the mechanical demands placed on vehicles today. According to a report by the Society of Automotive Engineers (SAE), the choice of sprockets not only affects torque delivery but also plays a crucial role in reducing wear and tear on both the chain and engine components.

As industry expert John Anderson, a renowned mechanical engineer with over 20 years of experience in the field, stated, "Selecting the appropriate chain sprockets is essential for enhancing the operational reliability of any vehicle." His insights underline the importance of understanding the specific requirements of your vehicle's drivetrain. By evaluating factors such as material compatibility, sprocket size, and tooth count, vehicle owners can ensure optimal performance. This guide will provide the top ten tips for making an informed decision, ultimately leading to enhanced vehicle safety and longevity.

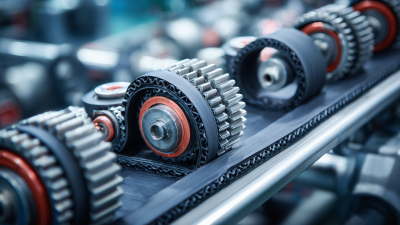

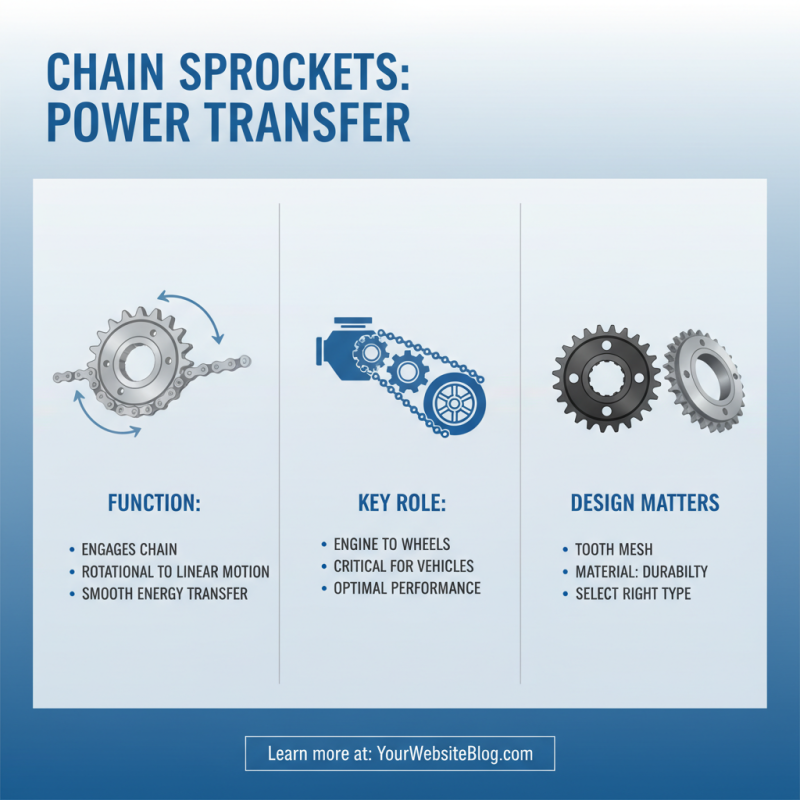

Chain sprockets are essential components in various vehicles, playing a critical role in the transfer of power from the engine to the wheels. Understanding their functionality is vital for maintaining optimal performance. At the core of a sprocket's role is its ability to engage with the chain, translating rotational motion into linear movement. Each tooth on the sprocket meshes with the links of the chain, allowing for a smooth and efficient transfer of energy. The design and material of the sprocket can significantly affect durability and performance, making it imperative to select the right type for your specific vehicle needs.

The interaction between the chain and sprocket is also influenced by several factors, such as the pitch, tooth count, and overall size. A correctly matched chain sprocket ensures minimal wear, reduces friction, and promotes longevity in both the chain and the sprocket itself. Key considerations include the vehicle's operating conditions, load requirements, and the speed at which it operates. By understanding these fundamentals, vehicle owners can make informed decisions that enhance performance and reliability in their machine's drivetrain system.

When selecting sprockets for your vehicle, several critical factors must be considered to ensure optimal performance and compatibility. First and foremost, the material of the sprockets significantly impacts durability and weight. Common materials include steel, aluminum, and plastic, each having its own strengths. For instance, a report from the Society of Automotive Engineers noted that high-carbon steel sprockets provide superior wear resistance and longevity, making them ideal for heavy-duty applications, while aluminum offers lightweight solutions for racing environments.

Another essential factor is the sprocket size and pitch. Proper sizing ensures alignment and operational efficiency, which ultimately influences power transfer and overall drivetrain performance. According to the American Gear Manufacturers Association, a mismatch in size can lead to increased wear and potential mechanical failure. Additionally, the tooth profile and count can affect acceleration and top speed, underscoring the need for precise calculations based on the vehicle's intended use. Ultimately, thorough consideration of these elements will guide vehicle owners towards selecting the most suitable sprockets, enhancing their vehicle's performance and reliability on the road.

When selecting chain sprockets for your vehicle, understanding the different material types and their impact on performance is crucial. Sprockets are commonly made from materials such as steel, aluminum, and plastic, each offering distinct advantages and disadvantages in terms of durability, weight, and cost. Steel sprockets, for instance, are renowned for their high strength and longevity, making them suitable for heavy-duty applications. However, they tend to be heavier than other options, which can affect overall vehicle performance, especially in racing or performance-centric scenarios.

Aluminum sprockets present a lighter alternative, which can enhance acceleration and agility. They are often preferred in competitive settings where weight savings are essential. However, while aluminum is resistant to corrosion, it may wear down faster than steel, particularly under extreme operational conditions. Plastic sprockets are another option, known for their lightweight and low friction properties. They are beneficial in reducing noise and improving efficiency but may not withstand high torque applications as effectively as metal counterparts. Ultimately, the choice of material should align with the specific demands of your vehicle, considering factors such as weight, durability, and intended use to ensure optimal performance.

| Material Type | Durability | Weight | Cost | Performance |

|---|---|---|---|---|

| Steel | High | Medium | Low | Excellent |

| Aluminum | Medium | Light | Medium | Good |

| Plastic | Low | Very Light | Low | Fair |

| Titanium | Very High | Medium | High | Excellent |

| Carbon Fiber | High | Very Light | Very High | Outstanding |

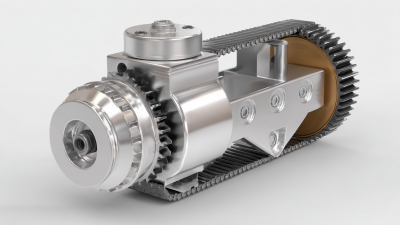

When selecting the right chain sprockets for your vehicle, precise measurement is crucial for optimal performance. Begin by identifying the pitch of the chain, which is the distance between the pins that connect the links. Using a caliper, measure the distance from the center of one pin to the center of the next. This measurement will help determine the appropriate sprocket size that will fit your existing chain without causing misalignment or excess wear.

Additionally, consider the number of teeth on the sprocket, as this will affect the gearing ratio and overall performance of your vehicle. A sprocket with more teeth will provide better torque but may reduce acceleration, while one with fewer teeth enhances speed but can decrease torque. Check the existing sprocket for the tooth count, as this will guide your selection. It's also advisable to note the width of the sprocket to ensure compatibility with your chain.

When choosing sprockets, keep in mind that material and construction play a significant role in durability and performance. Opt for sprockets made from high-strength materials to withstand wear and resist deformation, especially under heavy loads. Additionally, consider the intended use of your vehicle—whether it's for racing, off-road driving, or daily commuting—as this will influence which sprocket dimensions and specifications are appropriate for your needs.

Maintaining your sprockets is crucial for ensuring the longevity and efficiency of your vehicle's drivetrain. Regular inspections should be a key part of your maintenance routine. Check for signs of wear such as tooth degradation, excessive rust, or unusual play in the sprocket. Addressing these issues early can prevent more significant problems down the road, such as poor chain alignment or even complete drivetrain failure. It's also advisable to keep the sprockets clean, removing any built-up dirt and grime that can lead to increased friction and wear.

Lubrication is another vital aspect of sprocket maintenance. Applying the appropriate lubricant can significantly reduce wear on the sprockets and chain, enhancing the overall performance of your vehicle. However, it’s essential to avoid over-lubrication, as this can attract dirt and debris, creating more problems than it solves. Additionally, ensuring that the chain tension is correctly set can further enhance the lifespan of both the chain and sprockets, minimizing the chances of slippage or improper engagement. By following these best practices, you can maintain optimal function, reduce wear, and extend the life of your vehicle's transmission components.