Leave Your Message

-

Phone

-

E-mail

The rubber V belt is essential for efficient machinery operation. It transfers power between different components seamlessly. In 2026, choosing the best rubber V belts is crucial for optimal performance.

These belts must withstand wear and tear, offering durability under various loads. Manufacturers strive to create belts that balance flexibility and strength. However, not all options meet these standards. Some may fray or lose tension too quickly.

When selecting a rubber V belt, consider your specific application. Look for user reviews and performance ratings. Take a moment to reflect on past choices. Did they perform as expected? Identifying past mistakes can guide future selections. The right rubber V belt can enhance efficiency and reduce maintenance costs. Choosing wisely pays off in the long run.

Rubber V belts are essential components in many machinery. They transfer power efficiently from one component to another. Their design allows for smooth operation and reduced slippage. The unique shape of the V belt provides a larger surface area for gripping. This feature enhances the performance and lifespan of the belt.

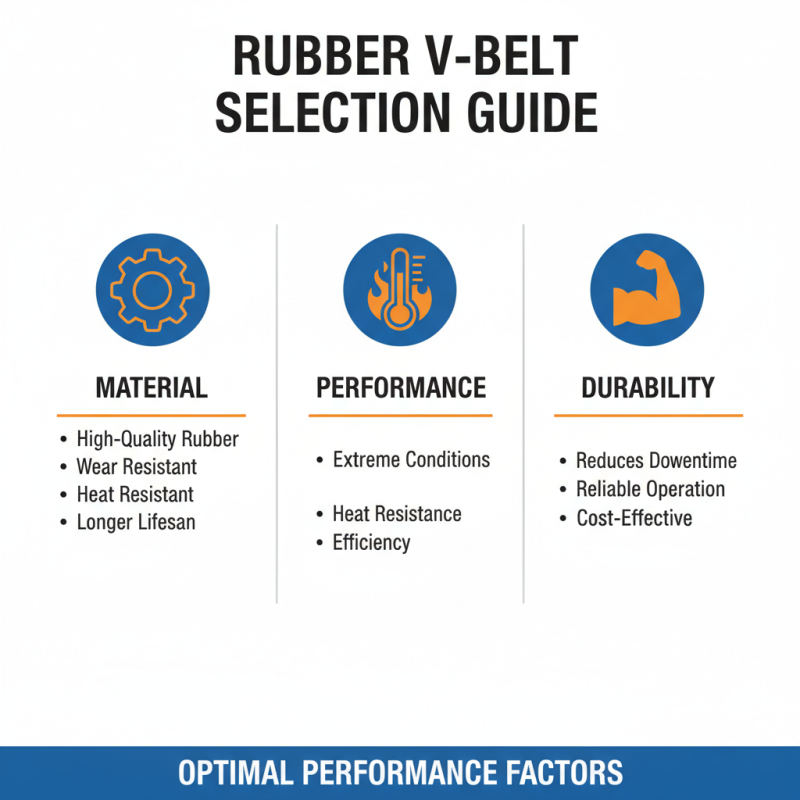

When selecting a rubber V belt, consider key features. The material quality matters greatly. High-grade rubber resists wear and weather. It can endure high temperatures and harsh conditions. Look for belts with proper flexibility. They need to bend easily without breaking. Noise levels are another aspect. A well-designed belt operates quietly, reducing disruptions.

Not all belts are perfect. Some may wear quicker than expected. Others might not fit as intended. Measuring correctly is crucial. A slight miscalculation can lead to inefficiency. Assessing your equipment requirements will lead to better choices. Choosing the right rubber V belt can significantly impact overall performance.

| Model | Length (inches) | Width (inches) | Material | Max Load (lbs) | Speed (RPM) | Benefits |

|---|---|---|---|---|---|---|

| Model A | 30 | 0.5 | Natural Rubber | 200 | 5000 | High durability and flexibility |

| Model B | 36 | 0.6 | Synthetic Rubber | 250 | 4500 | Excellent grip and heat resistance |

| Model C | 40 | 0.7 | Neoprene | 300 | 4700 | Superior oil and heat resistance |

| Model D | 42 | 0.4 | Polyurethane | 220 | 5300 | Low stretch and high efficiency |

| Model E | 38 | 0.75 | Rubber Composite | 280 | 4900 | Good shock absorption |

| Model F | 33 | 0.55 | SBR Rubber | 240 | 5100 | High wear resistance |

| Model G | 35 | 0.65 | Viton | 320 | 4600 | Resistant to extreme temperatures |

| Model H | 39 | 0.5 | EPDM | 210 | 5200 | Excellent ozone resistance |

| Model I | 31 | 0.6 | Silicone | 300 | 4500 | High elasticity and flexibility |

| Model J | 34 | 0.7 | Hypalon | 350 | 4800 | Superior chemical resistance |

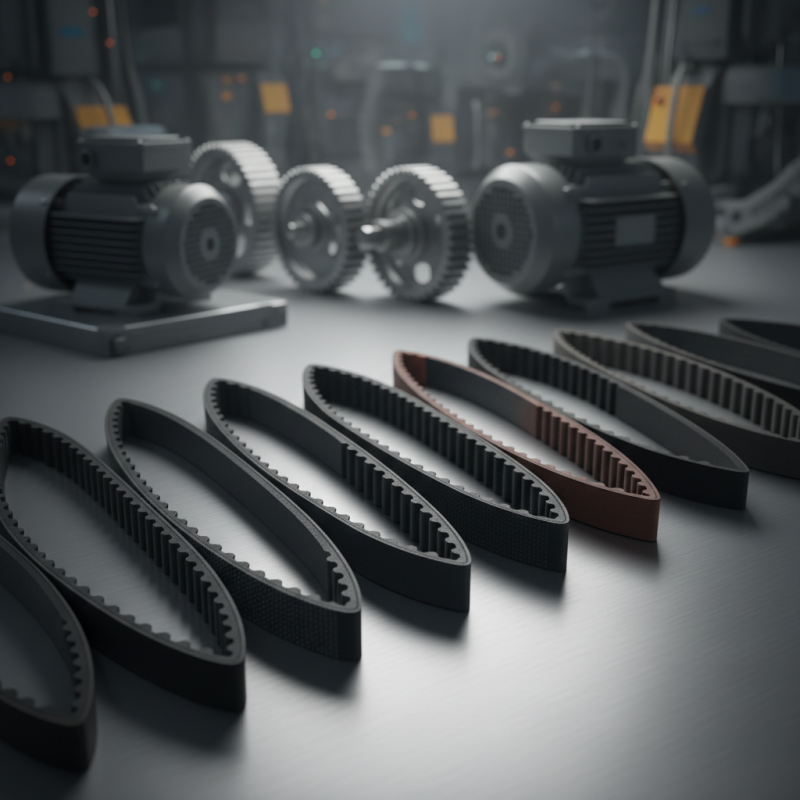

When selecting the best rubber V belts for 2026, several criteria must be considered. First, the material composition is essential. High-quality rubber, often blended with additives, improves durability. According to industry reports, belts made from EPDM rubber can last up to 30% longer than standard options. This is crucial for heavy-duty applications where performance is non-negotiable.

The belt's dimensional accuracy greatly impacts its performance. Precision measurements ensure proper fit and alignment in machinery. A report by the Mechanical Engineering Journal highlights that improper dimensions can lead to 15% efficiency loss. Additionally, temperature resistance plays a significant role. Rubbers designed for high heat can withstand extreme conditions. This can prevent failures during operation, which would otherwise cause costly downtimes.

Lastly, users must be aware of environmental factors. Belts exposed to oils and chemicals need special formulations. Yet, many overlook this aspect during selection. A failure to account for these variables could lead to premature wear. Balancing these factors will result in optimal performance in 2026. Regular maintenance also cannot be ignored. It plays a critical role in prolonging the lifespan of these belts.

When selecting rubber V belts for optimal performance, there are several factors to consider. The material itself plays a crucial role in durability and efficiency. High-quality rubber compounds ensure resistance to wear and heat, enhancing lifespan. However, some belts may not perform well under extreme conditions. Evaluating their heat resistance is essential.

Fitting and installation can't be overlooked. A poorly fitted belt can lead to premature wear and reduced performance. Incorrect tension can cause slippage. Regular checks on alignment and tension are necessary. Observations over time reveal that even small adjustments can make significant differences. It's a detail that should never be ignored.

Lastly, don't forget about maintenance. Regular inspections often uncover hidden wear signs. Small cracks or glazing might indicate it's time for replacement. On occasion, users encounter unexpected failures. It's essential to understand that no belt is perfect. Performance varies based on the application. Finding the right match requires ongoing testing and adaptation.

When selecting rubber V belts, it’s essential to consider the specific application. Different machines require unique specifications for optimal performance. For instance, industrial equipment often demands heavy-duty belts that withstand rigorous use. Conversely, automotive applications benefit from belts designed for flexibility and strength.

In high-temperature environments, belts made from specialized rubber compounds can reduce wear and ensure durability. It's important to evaluate the conditions the belt will face. Always ensure compatibility with the machinery.

Tips: Consider the operating temperature and load capacity. Measure the pulleys accurately. Regular maintenance can extend belt life. Improper installation may lead to premature failure.

Choosing the right rubber V belt is crucial for efficiency. Not all belts perform equally; some may slip under heavy loads. Testing different belt types is vital to find the best fit. A mismatch can cause significant downtime. Stay informed about the latest materials and technologies for optimal selection.

Maintaining rubber V belts is crucial for optimal performance. Regular checks can prevent premature failures. Ignoring signs of wear can lead to costly downtime. A study found that 40% of failures stem from insufficient maintenance.

Visual inspections should be routine. Look for fraying, cracking, or glazing. These are signs the belt is nearing its end. A worn belt can slip, affecting efficiency. Proper tension is vital. Over-tightening can cause unnecessary wear. It’s simple to check tension; just a quick pull can reveal excessive slack.

Lubrication is often misunderstood. Most rubber V belts do not require lubrication. Applying lubricant can attract dirt, causing more harm. Instead, keep the area clean. Monitor operating conditions. Extreme heat or cold can shorten lifespan. In fact, exposure to oil and chemicals can degrade rubber significantly. Assess your environment regularly. Taking these small steps can enhance belt longevity, ensuring smoother operation.

This bar chart illustrates the average lifespan (in years) and operating temperatures (in °C) of the top 10 rubber V belts, highlighting their optimal performance metrics for maintenance considerations.