Leave Your Message

-

Phone

-

E-mail

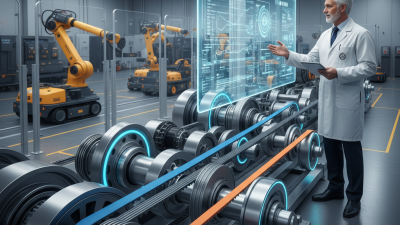

In the evolving world of industrial equipment, the significance of durable and high-performance components cannot be overstated. Among these, the Open End Belt stands out for its unique design and application versatility. As John Smith, a renowned expert in conveyor systems, aptly puts it, “The reliability of an Open End Belt can significantly enhance operational efficiency while minimizing downtime.” This statement underlines the crucial role that these belts play in a variety of industries, from manufacturing to logistics.

Choosing the right Open End Belt is essential, not only for efficiency but also for long-term cost-effectiveness. With numerous options available in the market, understanding the top contenders can be challenging. Factors such as material composition, tensile strength, and resistance to wear significantly influence performance and longevity. This article aims to present a comprehensive overview of the top 10 Open End Belts, emphasizing their unique features and optimal use cases. By examining these leading options, we will help industry professionals make informed decisions that align with their operational needs.

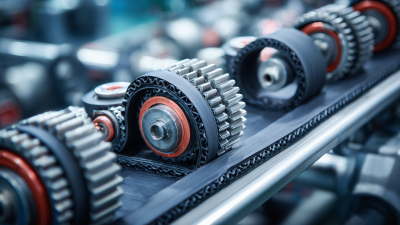

Open end belts, also known as continuous belts, are crucial components in various mechanical applications, providing enhanced durability and performance in systems that require efficient power transmission. These belts are typically made from flexible materials that allow for a seamless loop, making them ideal for conveyors, textile machinery, and even automotive systems. Their unique design minimizes slippage and wear, ensuring a longer lifespan compared to traditional belts.

When choosing open end belts, it's important to consider the material used, as it can significantly affect performance. For instance, rubber composites offer high resistance to wear and climate variations, while polyurethane is favored for its flexibility and strength. Additionally, the thickness and width of the belt should align with the specific requirements of your application to prevent premature failure.

Tips: Always ensure proper tension when installing open end belts to avoid excessive strain. Regularly inspecting for signs of wear can help identify issues before they become critical. Finally, consider the environment where the belt will be used; some materials perform better in extreme temperatures or exposure to chemicals.

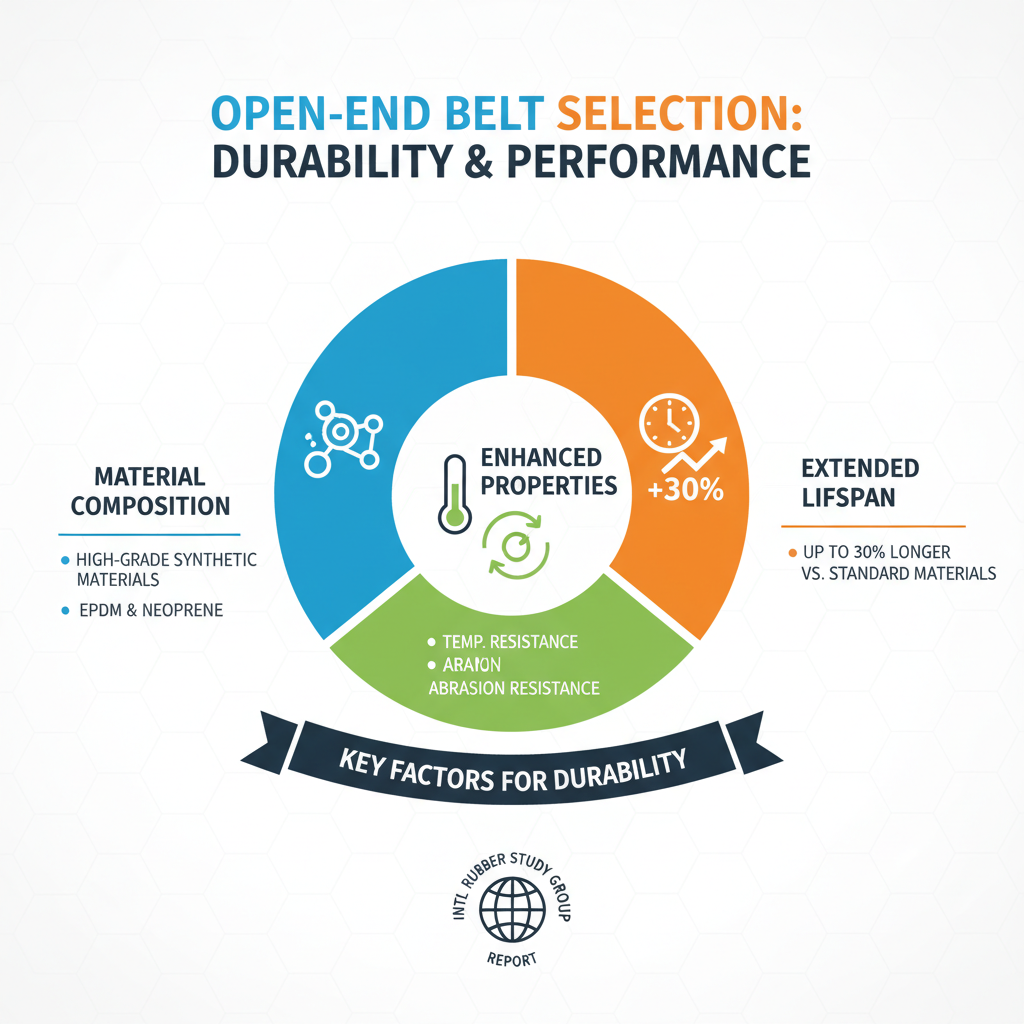

When selecting open end belts, several key factors play a crucial role in determining their durability and performance. One of the primary considerations is the material composition. According to a report by the International Rubber Study Group, the use of high-grade synthetic materials, such as EPDM and neoprene, significantly enhances the resilience of belts under extreme conditions. These materials can resist temperature variations and abrasions, extending the life of the belts by up to 30% compared to those made from standard materials.

Another influential factor is the manufacturing process. Many leading manufacturers utilize advanced techniques like precision molding, which ensures consistent thickness and reduces weak spots in the belt structure. A study by the Belt and Pulley Manufacturers Association found that belts produced with high precision techniques exhibit a failure rate that is 50% lower than those manufactured using conventional methods. Additionally, proper tension management and alignment during installation can further enhance the performance and durability of open end belts, as misalignment is a leading cause of premature wear.

When it comes to open end belts, durability and performance are crucial, and top brands are stepping up to meet these demands. Companies like Gates, Continental, and Goodyear are recognized for their advanced material technology and manufacturing processes, which ensure that their belts can withstand extreme conditions. According to a recent industry report from the Rubber Manufacturers Association, high-quality open end belts can last up to 30% longer than their cheaper counterparts, making them a wise investment for businesses relying on continuous operations.

Gates, for example, utilizes a patented manufacturing technique that enhances flexibility and strength, resulting in superior performance under high loads. Their open end belts have been tested to operate effectively at temperatures ranging from -40°F to 250°F, showcasing their capability in diverse environments. Similarly, Continental is known for its innovative polymer compounds that resist wear and tear, leading to a significant reduction in downtime and maintenance costs. A study by the Society of Automotive Engineers highlighted that switching to premium open end belts can increase overall system efficiency by more than 15%, making these brands the go-to choice for industries that prioritize reliability and longevity.

| Belt Type | Material | Width (inches) | Thickness (mm) | Max Load (lbs) | Temperature Range (°F) |

|---|---|---|---|---|---|

| Polymer | Polyurethane | 1.5 | 5 | 1500 | -40 to 200 |

| Rubber | Natural Rubber | 2.0 | 4 | 1200 | -30 to 180 |

| Polyester | Polyester Fiber | 1.0 | 3 | 1000 | -20 to 150 |

| Fabric | Nylon | 1.5 | 2 | 800 | -10 to 160 |

| Composite | Composite Material | 2.5 | 6 | 2000 | -50 to 220 |

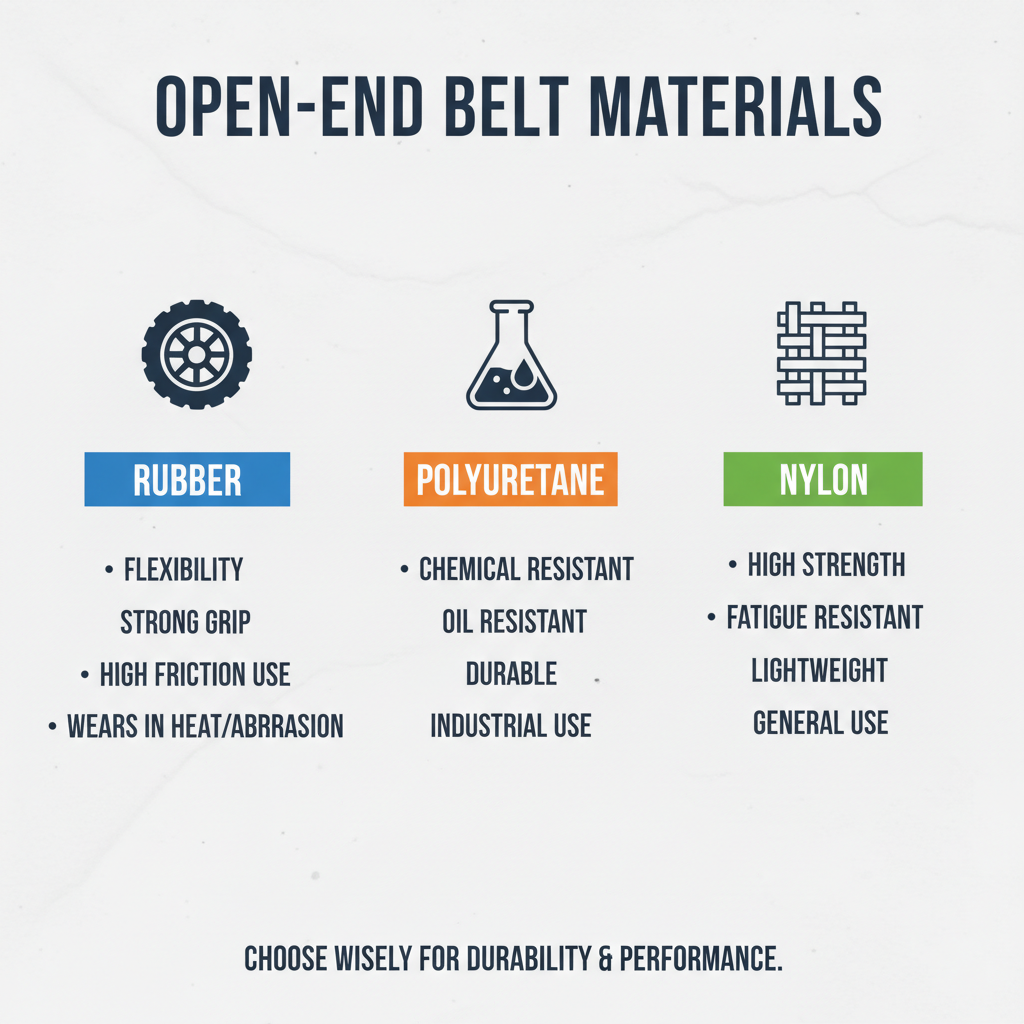

When evaluating open end belts, the material type significantly influences both durability and performance. Among the most commonly used materials are rubber, polyurethane, and nylon. Rubber belts are known for their excellent flexibility and grip, making them ideal for high-friction applications. However, they may wear out more quickly in extremely hot or abrasive environments. Conversely, polyurethane belts offer superior resistance to chemicals and oils, which enhances their longevity in challenging industrial settings.

Nylon, another popular choice, provides a balance between strength and flexibility but may not perform as well under heavy loads compared to rubber. The heat resistance of nylon can also be a concern; thus, it's less suited for applications involving high temperatures. Each material possesses unique properties that make it suitable for specific operational needs, and understanding these differences enables users to select the most appropriate open end belt for their application. The choice of material ultimately affects not just the belt's lifespan and performance but also the overall efficiency of the machinery in which they are used.

To enhance the longevity of open end belts, regular maintenance is essential. One of the most effective practices is to conduct frequent inspections for signs of wear and tear. Check for fraying edges, cracks, or any signs of fatigue in the material. By identifying issues early, you can prevent further damage and extend the operational life of the belt. Additionally, ensure that the belt tension is properly adjusted; overly tight or loose belts can lead to premature wear.

Another crucial maintenance tip is to keep the belt clean and free from debris. Accumulation of dirt, dust, and other contaminants can interfere with the belt's performance and lead to excess wear. Use a soft brush or cloth to gently remove any buildup. Furthermore, applying appropriate lubricants can reduce friction and help maintain optimal performance under various operating conditions. Always use lubricants recommended by the manufacturer to ensure compatibility with the belt material. By following these maintenance practices, you can significantly improve the durability and effectiveness of open end belts.