Leave Your Message

-

Phone

-

E-mail

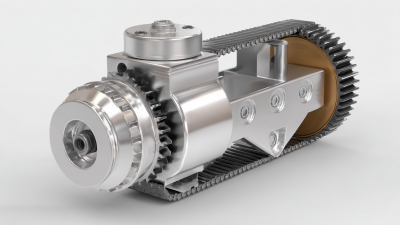

In the evolving landscape of industrial machinery and power transmission,

poly belts have emerged as a critical component for enhancing performance and durability.

According to the latest industry report by Market Research Future, the global poly belts market is projected to grow at a CAGR of 5.9% from 2021 to 2028, driven by the increasing demand for efficient energy transmission solutions across various sectors.

This significant growth underscores the importance of selecting the right type of poly belt for specific applications.

Industry expert Dr. James Anderson, a leading consultant in power transmission systems, emphasizes,

"The effectiveness of poly belts in reducing friction and wear directly translates to improved machinery longevity and operational efficiency."In 2025, choosing the right poly belt type will be crucial for industries aiming to optimize their processes while minimizing maintenance costs. As we delve into the top poly belts available in 2025, it is essential to consider the unique characteristics and applications of each type to enhance overall performance and durability, ensuring that businesses can remain competitive in a rapidly advancing market.

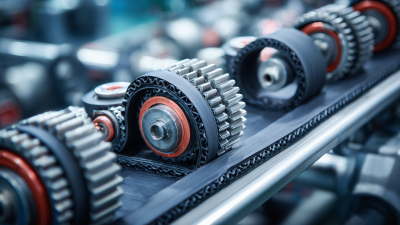

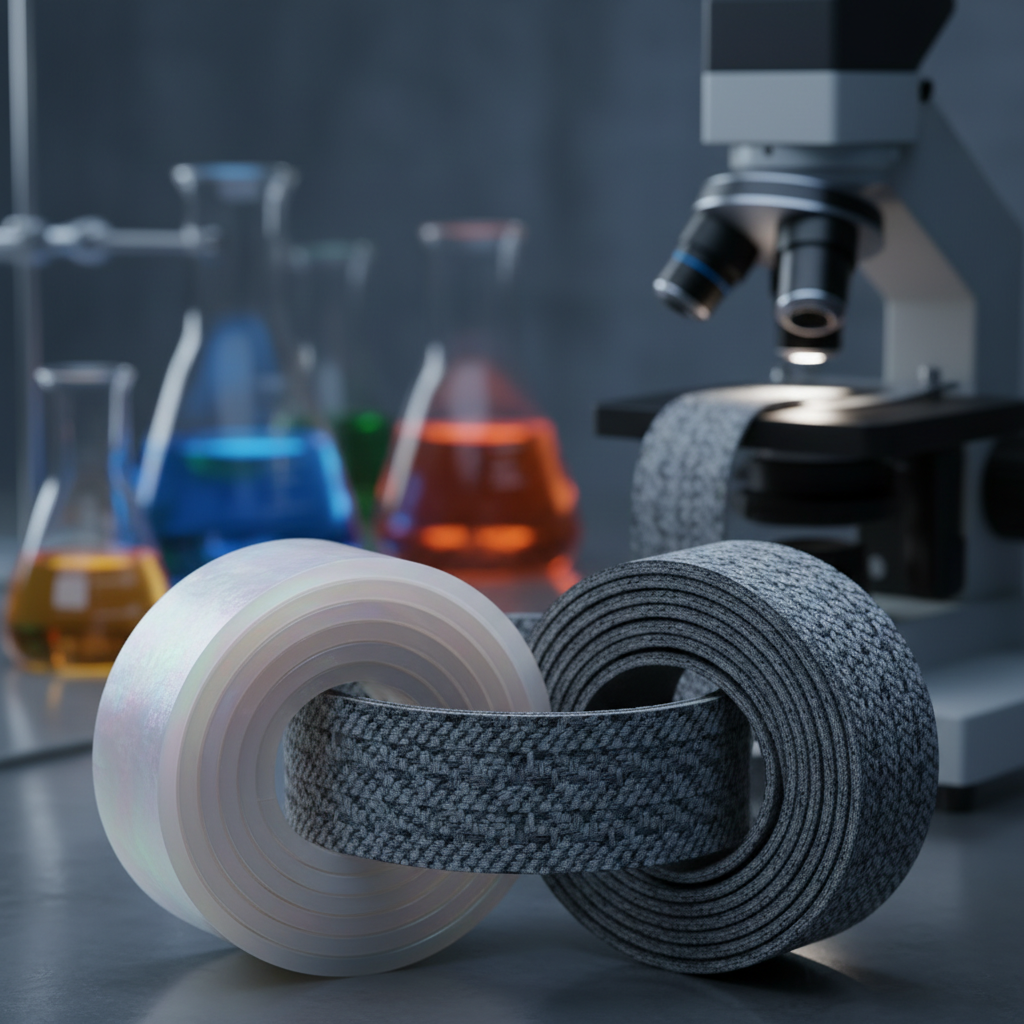

As industries evolve, so do the materials and designs used in power transmission systems. In 2025, new types of poly belts are emerging to address the increasing demand for enhanced efficiency and durability. One of the standout innovations is the use of thermoplastic elastomers (TPEs), which offer superior flexibility and resilience compared to traditional rubber materials. These TPE-based belts not only withstand higher temperatures but also excel in environments with exposure to chemicals and oils, making them ideal for diverse applications across manufacturing and automotive sectors.

Another exciting development is the integration of advanced wear-resistant coatings on poly belts. These coatings enhance the belts' longevity by significantly reducing friction and minimizing abrasion during operation. Additionally, manufacturers are exploring new composite materials that merge the best characteristics of various polymers to create belts that balance flexibility with strength. These emerging poly belts are designed to deliver peak performance under extreme conditions, thereby optimizing the overall efficiency of machinery and reducing maintenance costs. As technology continues to advance, these innovative poly belts will undoubtedly play a pivotal role in shaping the future of industrial performance.

In recent years, the demand for high-performance poly belts has surged, driven by advancements in material science. Innovative materials, such as thermoplastic elastomers (TPEs) and advanced polyester composites, have become pivotal in enhancing the durability and performance of poly belts. According to a report by MarketsandMarkets, the poly belt market is expected to grow at a CAGR of 5.3% from 2020 to 2025, indicating a robust shift towards more resilient belt solutions that cater to industrial applications.

One of the key developments is the incorporation of reinforced polyamide fibers, which significantly improve the tensile strength and flexibility of belts. With a breaking strength increase of up to 40% when compared to traditional materials, these advanced fibers allow poly belts to perform efficiently in high-stress environments.

Furthermore, the introduction of UV-resistant additives and anti-friction coatings has extended service lives and reduced maintenance costs, making poly belts an increasingly cost-effective option for manufacturers. As industries increasingly prioritize sustainability and performance, the evolution of poly belt materials will play a crucial role in optimizing operations across various sectors.

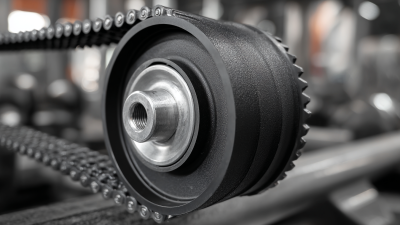

In the competitive landscape of industrial applications, the choice of poly belts can dramatically influence operational efficiency and equipment longevity. A recent report by the Intercontinental Rubber Association highlighted that the use of high-performance poly belts can lead to a 15-25% increase in conveyor system efficiencies compared to standard models. This notable improvement is largely due to enhanced material properties, which allow poly belts to withstand higher loads and reduce friction, resulting in lower energy consumption and decreased wear over time.

When analyzing the different types of poly belts available, it's crucial to consider their specific applications. For instance, polyurethane belts are ideal for applications requiring superb abrasion resistance and tensile strength, making them suitable for heavy-duty industries such as automotive and mining. According to a study conducted by the Polyurethane Manufacturers Association, these belts demonstrate a lifespan up to 50% longer than traditional rubber belts in similar conditions. Furthermore, thermoplastic elastomer belts offer flexibility and resistance to extreme temperatures, which can be vital in industries like food processing where hygiene and durability are paramount. Thus, selecting the appropriate poly belt type not only enhances performance but also contributes to substantial cost savings over time.

As we move towards 2025, the poly belt technology is expected to undergo significant advancements aimed at enhancing performance and durability. Industry experts predict a shift towards more sustainable materials, with a projected market growth of 5.6% annually for poly-based products, indicating a rising demand for environmentally friendly solutions that do not compromise on efficiency. Innovations in chemical formulations are likely to improve heat resistance and reduce wear, extending the lifespan of poly belts in various applications.

Tip: When selecting poly belts, consider the specific environmental conditions of your operation. For instance, belts designed for high-temperature applications will outperform standard options in similar settings, resulting in lower maintenance costs and increased productivity.

The integration of smart technology within poly belts is another future trend to watch. Reports suggest that sensors embedded in belts could monitor wear and performance in real-time, providing invaluable data for predictive maintenance. This approach not only enhances operational efficiency but also helps in minimizing unplanned downtimes by alerting users to potential issues before they escalate.

Tip: Stay ahead of the curve by investing in smart poly belt systems that offer real-time analytics. This proactive approach can help you optimize your process and reduce costs associated with unexpected failures.

| Belt Type | Material Composition | Load Capacity (lbs) | Temperature Resistance (°F) | Expected Lifespan (Years) | Key Features |

|---|---|---|---|---|---|

| Polyester Reinforced | Polyester and Urethane | 1500 | -40 to 220 | 5 | High abrasion resistance, Low stretch |

| Polypropylene | Polypropylene Blend | 1200 | -20 to 180 | 6 | Lightweight, Chemical resistance |

| Aramid Fiber Reinforced | Aramid and Urethane | 2000 | -50 to 300 | 7 | High tensile strength, Extreme temperature tolerance |

| PVC Coated | PVC and Polyester | 1000 | -10 to 200 | 4 | Water resistant, Flexible |

| Rubberized Poly | Rubber and Polyblend | 1800 | -30 to 220 | 5 | Shock absorbing, Good grip |

When selecting poly belts for optimal performance and durability, several key factors come into play. The choice of material is paramount; poly belts can be made from various polymers, each offering different levels of strength and flexibility.

According to a report by the International Journal of Mechanical Engineering, belts made from polyurethane exhibit superior wear resistance and longevity compared to traditional rubber belts, often lasting up to 50% longer in high-load scenarios. This can translate into reduced maintenance costs and increased uptime for machinery.

Another critical consideration is the belt's construction and design characteristics. V-belts and synchronous belts are popular choices, with synchronous belts offering better power transmission efficiency, as reported by the American Society of Mechanical Engineers (ASME).

Furthermore, factors like temperature range, environmental exposure, and specific application needs can influence the performance of poly belts. For instance, belts designed for high-temperature environments are typically blended with special additives, enhancing their durability under extreme conditions.

Therefore, understanding these factors is essential to select the right poly belt that meets the specific demands of industrial applications.