Leave Your Message

-

Phone

-

E-mail

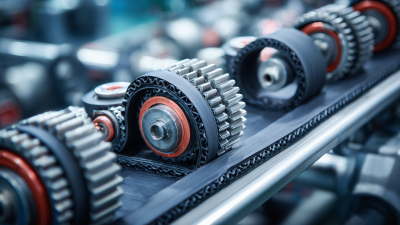

As industries continuously seek methods to enhance performance and efficiency, the focus on technological advancements becomes crucial. One significant component in achieving these goals is the Synchronous Belt. These belts, known for their precision and reliability, play a vital role in a variety of applications, including automotive, manufacturing, and automation processes. The evolving landscape of synchronous belt technology is set to experience transformative trends by 2025, driven by innovations that increase durability, reduce maintenance, and optimize operational efficiency.

In this exploration of the "Top 5" trends impacting synchronous belts, we will delve into the advancements that promise to enhance their functionality. From advancements in materials that improve wear resistance to the integration of smart technology that monitors performance in real time, the future of synchronous belts is poised for significant evolution. By understanding these trends, businesses can equip themselves to leverage these innovations, ensuring that they remain competitive in an ever-changing market while maximizing productivity and minimizing downtime.

The synchronous belt market is anticipated to witness significant innovations in materials by 2025, as manufacturers increasingly focus on enhancing performance and efficiency. Emerging materials, such as advanced polymers and composite materials, are being developed to withstand higher loads and operational stresses. According to a recent industry report by Grand View Research, the global synchronous belt market size was valued at approximately $3.5 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 5.6% by 2028. This growth can be attributed to the rising demand for more durable and efficient power transmission solutions across various sectors, including automotive and industrial machinery.

The integration of smart materials in synchronous belts also offers promising prospects for performance enhancement. These materials can adapt to different environmental conditions, improving energy efficiency and reducing maintenance costs. For instance, the use of thermo-responsive polymers not only improves the operational life of belts but also allows for real-time feedback on performance. The shift towards these innovative materials is driven by the need for sustainability and cost-effectiveness, with studies indicating that advanced material applications can lead to efficiency improvements of up to 30% in power transmission systems. As 2025 approaches, the emphasis on these emerging materials will define the future landscape of synchronous belt technology.

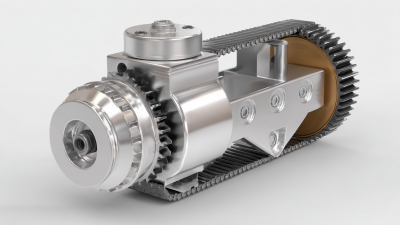

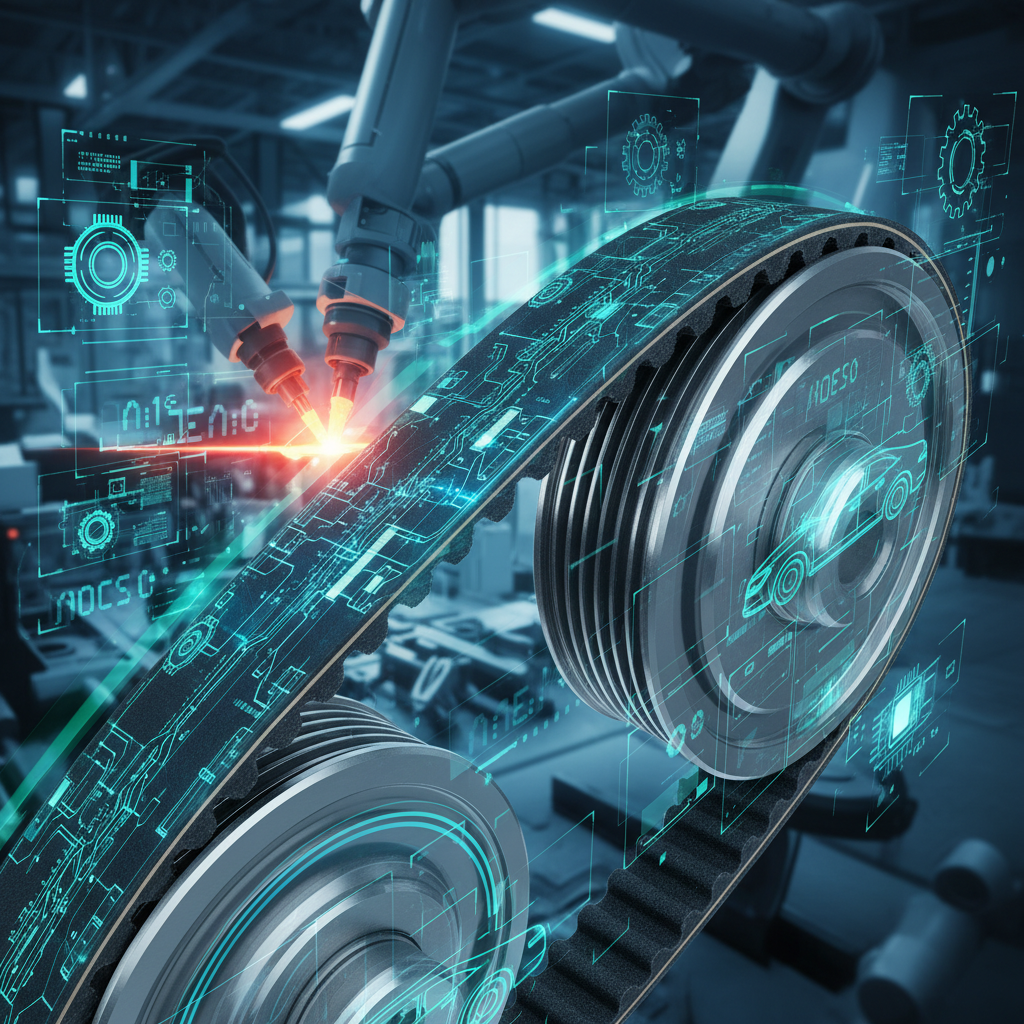

The impact of advanced manufacturing processes on the efficiency of synchronous belts is becoming increasingly significant as the automotive industry evolves. As highlighted in the Automotive Timing Belt Market Size report, projections estimate that the market will surpass USD 11.12 billion by 2034 due to factors such as rising vehicle ownership and the increasing demand for maintenance. The integration of AI-driven technologies in the manufacturing process is transforming how belts are designed and produced, allowing for enhanced precision and performance.

Furthermore, the global power transmission belting market is poised to reach an impressive USD 24.02 billion by 2034, starting from an estimated USD 12.69 billion in 2025. This growth indicates that streamlined manufacturing techniques and innovative materials are playing a crucial role in improving the overall efficiency of synchronous belts. As manufacturers adopt advanced processes such as automated production and real-time data analysis, the resulting belts not only demonstrate better durability but also contribute to more efficient power transmission mechanisms in automotive applications.

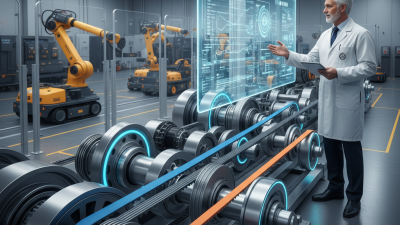

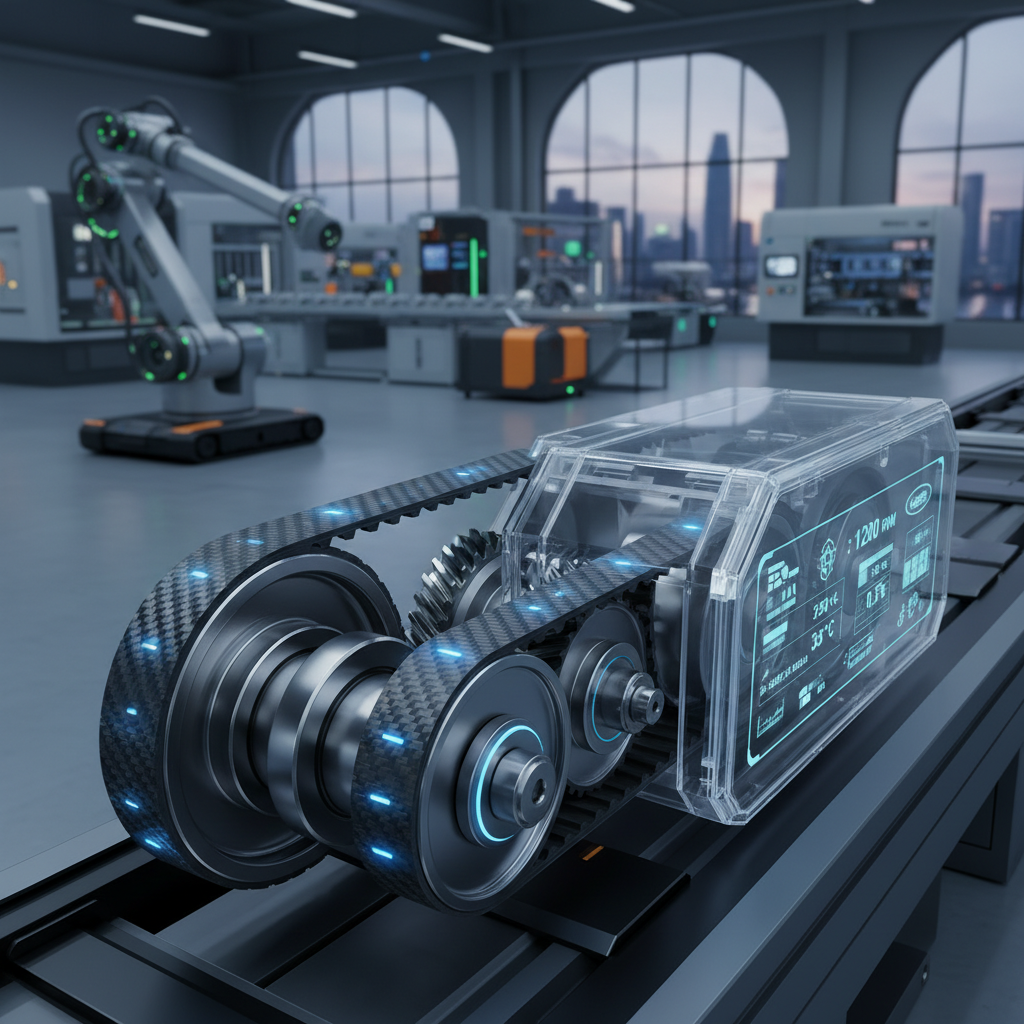

The integration of smart technology into synchronous belt systems is reshaping the landscape of performance and efficiency. As industries seek to enhance productivity, smart sensors and IoT-enabled devices are being incorporated into belt systems, allowing for real-time monitoring and data collection. This advancement empowers operators to track the operational status of belts, detect any anomalies, and perform predictive maintenance. The result is a significant reduction in downtime and maintenance costs, fostering a more resilient manufacturing environment.

Moreover, machine learning algorithms are being utilized to analyze the data collected from these smart systems. By leveraging this analysis, businesses can optimize belt performance based on specific operational conditions, leading to improved energy efficiency and longevity of the equipment. As we move towards 2025, the convergence of smart technology with synchronous belt systems promises not only enhanced performance but also a more sustainable approach to manufacturing, demonstrating a commitment to innovation and efficiency in modern industry.

The focus on sustainable practices in synchronous belt production is becoming increasingly crucial, driven by the need for reduced environmental impact and improved efficiency in manufacturing. As industries strive to implement greener processes, synchronous belt manufacturers are identifying ways to minimize waste and enhance product lifecycle management. This adaptation not only meets regulatory demands but also aligns with consumer preferences for sustainable products.

Market trends show a significant shift towards the adoption of sustainability in production. From the extraction of raw materials to the final distribution of synchronous belts, companies are exploring eco-friendly materials and methods. A report indicated that the market for sustainable adhesives, which plays a vital role in the production process, is projected to grow from $5.23 billion in 2025 to over $22.4 billion by 2032, reflecting a compound annual growth rate of 7.53%. This shift indicates a broader movement within the industrial sector towards sustainability and large-scale efficiency.

**Tips:** When analyzing market trends, consider the growing consumer demand for green alternatives and the impact of regulations on production processes. Keeping abreast of technological innovations can also provide insights into emerging practices that enhance both performance and sustainability in manufacturing.

The global synchronous belt market is poised for significant growth leading up to 2025 and beyond, reflecting an increasing demand for enhanced performance and efficiency across various industries. Forecasts suggest that the market will experience substantial expansion as manufacturers focus on improving the durability and operational capabilities of synchronous belts. The anticipated advancements in material technology and design are expected to drive performance enhancements, making these belts essential components in sectors such as automotive, manufacturing, and automation.

Simultaneously, the global artificial intelligence market is projected to grow from $294.16 billion in 2025 to an astonishing $1,771.66 billion by 2032, representing a remarkable compound annual growth rate (CAGR) of around 26.2%. This surge underscores the critical role AI technologies will play in optimizing supply chain management and boosting operational efficiency, further amplifying the demand for precision components like synchronous belts. As industries increasingly rely on automated systems and smart technologies, the integration of high-performance synchronous belts will be essential to accommodate these trends.