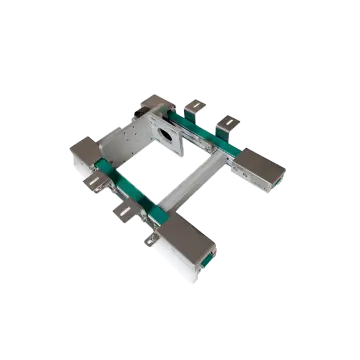

Custom Double-Sided Timing Belts - Premium Manufacturer & Supplier Solutions

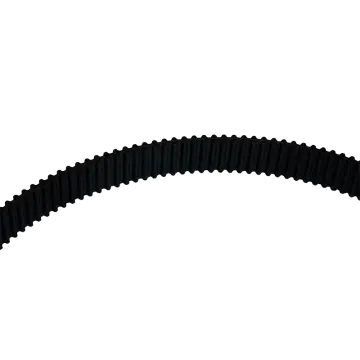

Our Double-Sided Timing Belt provides precision and reliability, specifically engineered for OEM applications. Manufactured with a focus on quality and durability, each belt is crafted to meet the rigorous demands of various manufacturing processes, ensuring outstanding performance. These belts are ideal for factories that require reliable and synchronized movement, enhancing machine efficiency. Upgrade your equipment or source essential components with our timing belts, designed to deliver exceptional strength and flexibility for your production lines.10 Essential Tips For Double-Sided Timing Belt Dominates Factory-Direct Excellence

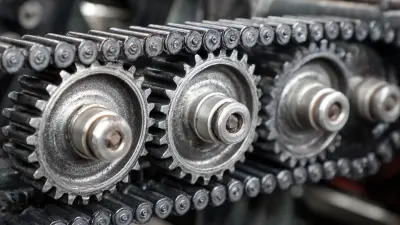

When it comes to Industrial Timing Belts, double-sided options offer unique advantages that can significantly enhance operational efficiency. Here are ten essential tips to ensure you select the best double-sided timing belts for your factory-direct needs. Firstly, understand the specific application requirements. The right belt selection depends on load capacity, speed, and environmental conditions. Consider the material construction of the belt; opting for high-quality materials can yield better durability and performance. Regular maintenance is crucial for longevity, so establish a routine inspection plan to catch wear and tear early. Moreover, the manufacturing process significantly impacts product quality. Choose suppliers with advanced manufacturing techniques and quality control systems in place. This ensures you receive belts that meet international standards and reduce the risk of failure. Lastly, an effective collaboration with manufacturers can lead to customized solutions tailored to your unique specifications, further maximizing operational excellence. By following these tips, you can enhance production efficiency while minimizing downtime and costs.

10 Essential Tips For Double-Sided Timing Belt Dominates Factory-Direct Excellence

| Tip Number | Tip Description | Expected Benefit |

|---|---|---|

| 1 | Regularly inspect timing belts for wear | Prevents unexpected machinery failure |

| 2 | Ensure proper tensioning of the belts | Enhances performance and lifespan |

| 3 | Choose high-quality materials | Reduces risk of belt deterioration |

| 4 | Maintain cleanliness in timing belt area | Prevents debris from accelerating wear |

| 5 | Monitor operating temperatures | Avoids heat-related damage |

| 6 | Schedule routine maintenance checks | Ensures proactive identification of issues |

| 7 | Install belts correctly to avoid misalignment | Maximizes efficiency and reduces wear |

| 8 | Utilize tension gauges for accurate measurements | Improves tension precision |

| 9 | Replace belts at recommended intervals | Prevents breakdowns and enhances reliability |

| 10 | Consult with experts for best practices | Ensures adherence to industry standards |

Why Professionals Prefer Double-Sided Timing Belt Service Backed by Expertise Dominates

J

Jackson Martin

Excellent durability! The after-sales support team provided insightful and timely assistance.

22 June 2025

D

Daniel Turner

I am very satisfied with the quality. Their after-sales service was attentive, and the representatives were very knowledgeable.

09 May 2025

D

David Bailey

This item did not disappoint! The after-sales service was superb, with knowledgeable staff ready to assist.

24 May 2025

N

Nathan Edwards

Great quality and great service! The support team provided useful advice and was very professional.

01 July 2025

C

Caleb Martin

This product has not let me down! The customer service team was efficient and very knowledgeable.

20 May 2025

J

Jonathan Clark

Great value and quality! The after-sales service was responsive and incredibly professional.

28 June 2025