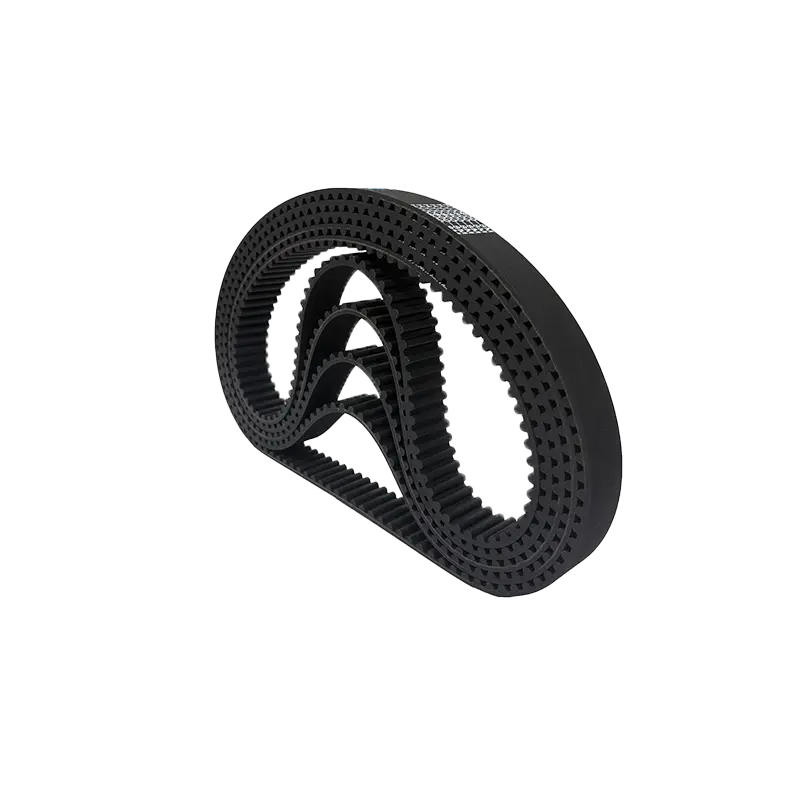

Industrial-grade rubber timing belt | Precision transmission solutions | Support customized production

description1

description2

Figure1: Physicomechanical Property of Synchronous Belt

|

Item |

Trapezoid tooth |

Arc tooth |

|||||||||||||

|

MXL |

XL |

L |

H |

XH |

XXH |

T2.5 |

T5 AT5 |

T10 AT10 |

T20 AT20 |

3M S3M |

S4.5M 5M S5M |

8M S8M |

14M S14M |

20M |

|

|

≥ Tensile strength(N/mm) |

45 |

80 |

120 |

270 |

380 |

450 |

45 |

80 |

270 |

380 |

90 |

160 |

300 |

400 |

520 |

|

N/mm Reference rate |

35 |

60 |

90 |

220 |

300 |

360 |

35 |

60 |

220 |

300 |

70 |

130 |

240 |

320 |

410 |

|

% Elongation rate ≤ |

4.0 |

||||||||||||||

|

Hardness(Shore A) |

75°±5° |

||||||||||||||

|

(N/mm) Cloth adhesion strength ≥ |

/ |

5 |

6.5 |

8 |

10 |

12 |

/ |

5 |

8 |

10 |

/ |

6 |

10 |

12 |

15 |

|

(N/mm) Cord adhesion strength ≥ |

/ |

200 |

380 |

600 |

800 |

1500 |

/ |

200 |

600 |

800 |

/ |

400 |

700 |

1200 |

1600 |

|

(N/mm) Tooth shear strenth ≥ |

/ |

50 |

60 |

70 |

75 |

90 |

/ |

50 |

70 |

75 |

/ |

50 |

60 |

80 |

100 |

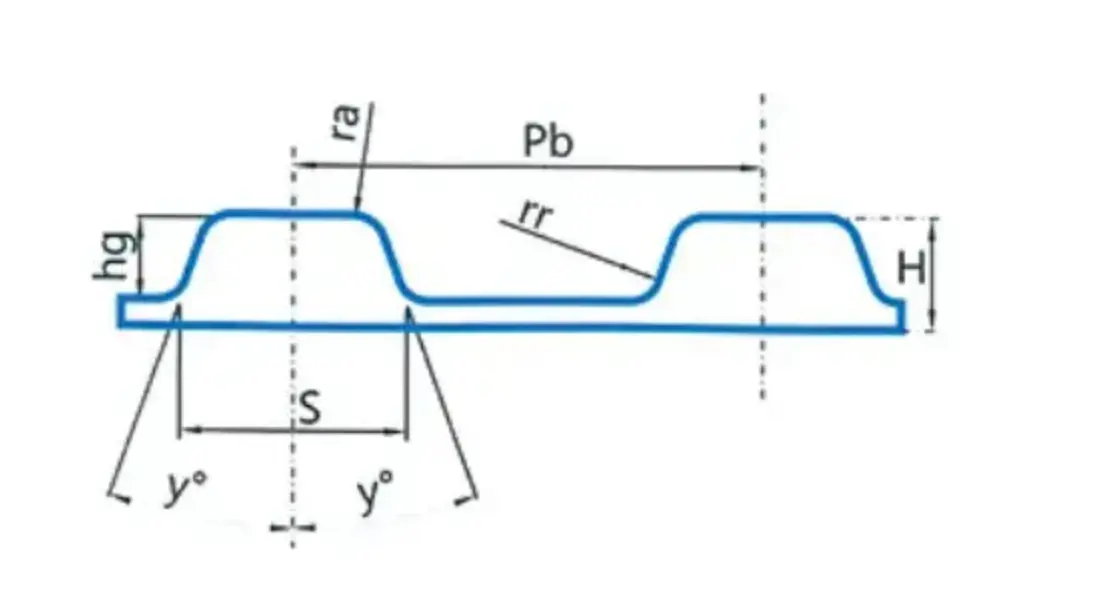

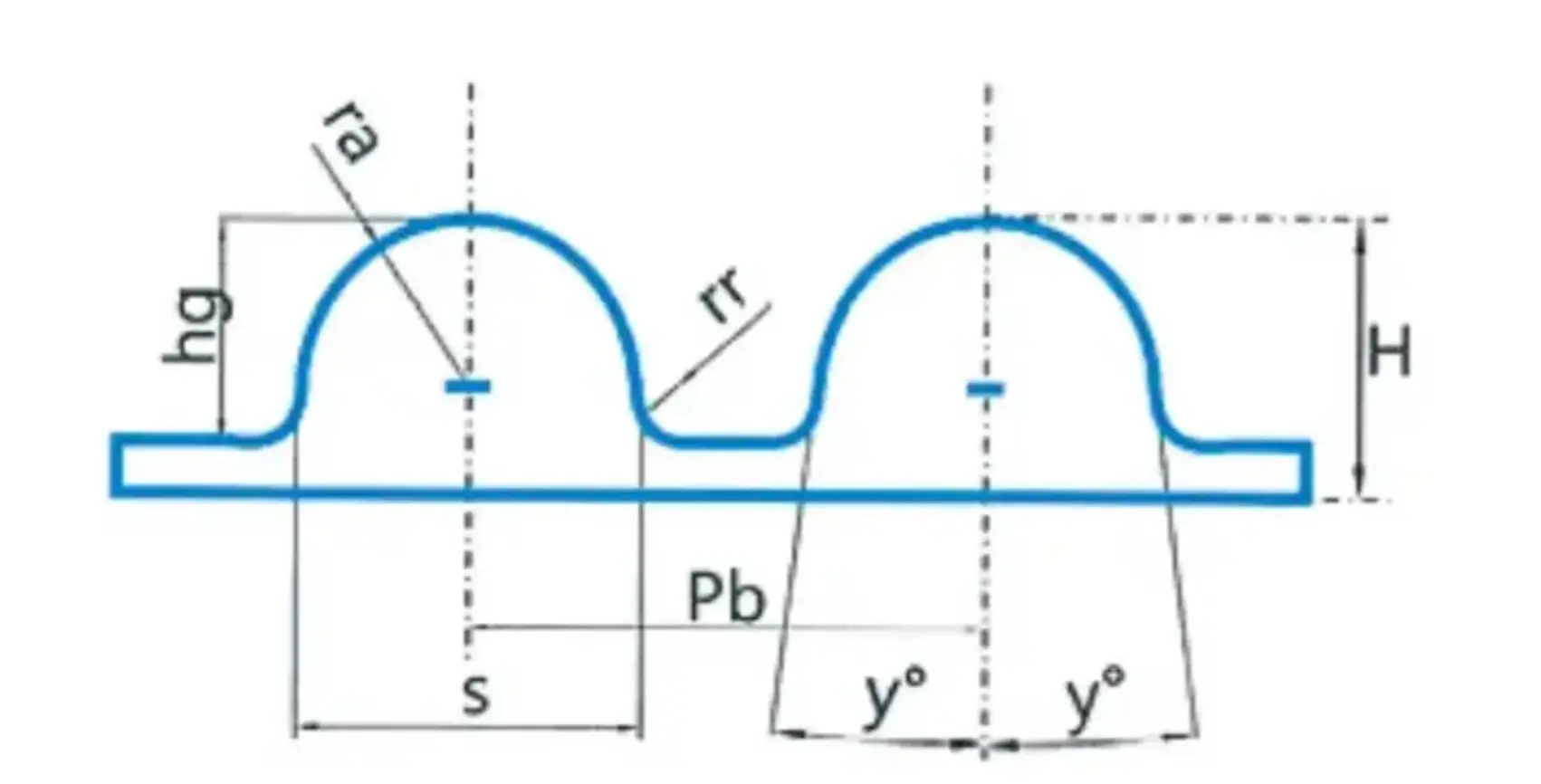

Figure2: Belt tooth size

|

TYPE |

Pitch |

Tooth angle |

Bottom tooth thickness |

Tooth height |

Fillet |

Tip |

Belt thickness |

Teeth number range |

Pitch length |

|

Pb |

2y° |

S |

hg |

rr |

ra |

H |

|||

|

MXL |

2.032 |

40 |

1.14 |

0.51 |

0.13 |

0.13 |

1.14 |

43~2044 |

87.38~4153.41 |

|

XXL |

3.175 |

50 |

1.73 |

0.76 |

0.20 |

0.20 |

1.52 |

46~124 |

146.05~393.70 |

|

XL |

5.080 |

2.57 |

1.27 |

0.38 |

0.38 |

2.30 |

22~510 |

111.76~2590.80 |

|

|

L |

9.525 |

40 |

4.65 |

1.91 |

0.51 |

0.51 |

3.60 |

23~530 |

219.08~5048.25 |

|

H |

12.700 |

6.12 |

2.29 |

1.02 |

1.02 |

4.30 |

29~440 |

368.30~5588.00 |

|

|

XH |

22.225 |

12.57 |

6.35 |

1.57 |

1.19 |

11.20 |

53~220 |

1177.93~4889.50 |

|

|

XXH |

31.750 |

19.05 |

9.53 |

2.29 |

1.52 |

15.70 |

56~144 |

1778.00~4572.00 |

Trapezoidal Toothed Synchronous Belt

|

TYPE |

Pitch |

Tooth angle |

Bottom tooth thickness |

Tooth height |

Fillet |

Tip |

Belt thickness |

Teeth number range |

Pitch length |

|

Pb |

2y° |

S |

hg |

rr |

ra |

H |

|||

|

T2.5 |

2.5 |

40 |

1.50 |

0.70 |

0.20 |

0.20 |

1.30 |

42~312 |

105.00~780.00 |

|

T5 |

5 |

2.65 |

1.20 |

0.40 |

0.40 |

2.20 |

30~400 |

150.00~2000.00 |

|

|

T10 |

10 |

5.30 |

2.50 |

0.60 |

0.60 |

4.50 |

34~536 |

340.00~5360.00 |

|

|

T20 |

20 |

10.15 |

5.00 |

0.80 |

0.80 |

8.00 |

61~181 |

1220.00~3620.00 |

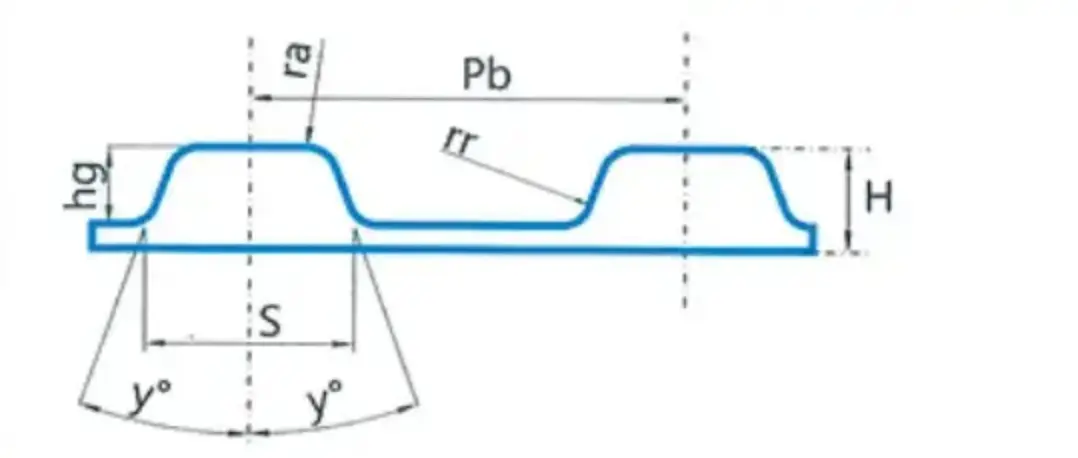

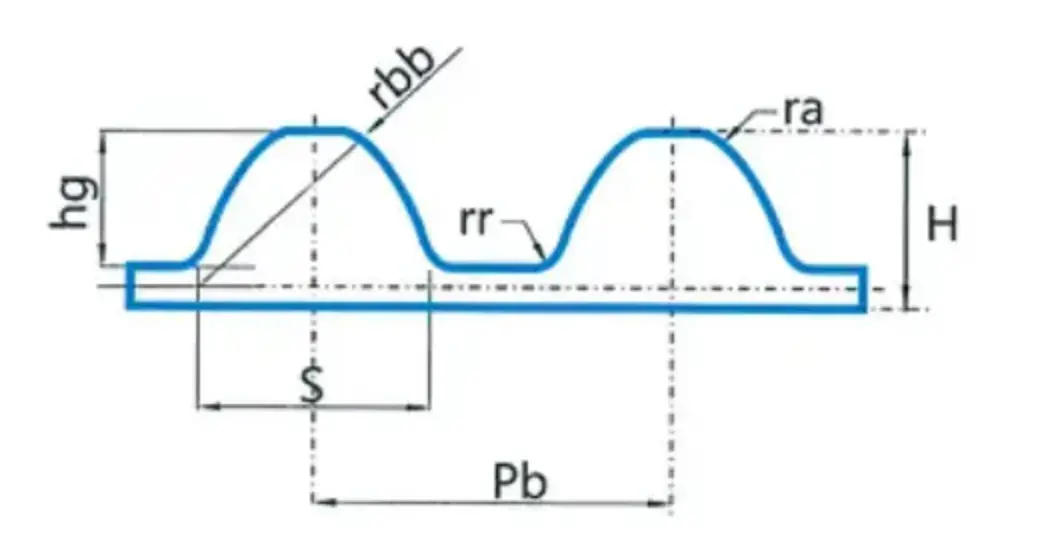

Arc Synchronous Belt

|

TYPE |

Pitch |

Tooth angle |

Bottom tooth thickness |

Tooth height |

Fillet |

Tip |

Belt thickness |

Teeth number range |

Pitch length |

|

Pb |

2y° |

S |

hg |

rr |

ra |

H |

|||

|

3M |

3 |

14 |

1.78 |

1.17 |

0.24-0.30 |

0.87 |

2.40 |

35~1000 |

105.00~3000.00 |

|

5M |

5 |

3.05 |

2.06 |

0.40-0.44 |

1.46 |

3.80 |

35~852 |

175.00~4260.00 |

|

|

8M |

8 |

5.15 |

3.36 |

0.64-0.76 |

2.46 |

6.00 |

36~565 |

288.00~4520.00 |

|

|

14M |

14 |

9.40 |

6.02 |

1.20-1.35 |

4.50 |

10.00 |

56~340 |

784.00~4760.00 |

|

|

20M |

20 |

14.00 |

8.40 |

1.77-2.01 |

6.50 |

13.20 |

100~260 |

2000.00~5200.00 |

S-toothed Synchronous Belt

|

TYPE |

Pitch |

Tooth angle |

Bottom tooth thickness |

Tooth height |

Fillet |

Tip |

Belt thickness |

Teeth number range |

Pitch length |

|

Pb |

2y° |

S |

hg |

rr |

ra |

H |

|||

|

S2M |

2 |

1.30 |

0.76 |

1.30 |

0.20 |

0.20 |

1.36 |

44~1914 |

88.00~3828.00 |

|

S3M |

3 |

1.95 |

1.14 |

1.95 |

0.30 |

0.30 |

1.94 |

41~500 |

123.00~1500.00 |

|

S4.5M |

4.5 |

2.93 |

1.71 |

2.93 |

0.45 |

0.45 |

2.81 |

40~201 |

180.00~904.50 |

|

S5M |

5 |

3.25 |

1.91 |

3.25 |

0.50 |

0.50 |

3.41 |

30~560 |

150.00~2800.00 |

|

S8M |

8 |

5.20 |

3.05 |

5.20 |

0.80 |

0.80 |

5.30 |

53~500 |

424.00~4000.00 |

|

S14M |

14 |

9.10 |

5.30 |

9.10 |

1.40 |

1.40 |

10.20 |

69~322 |

966.00~4508.00 |

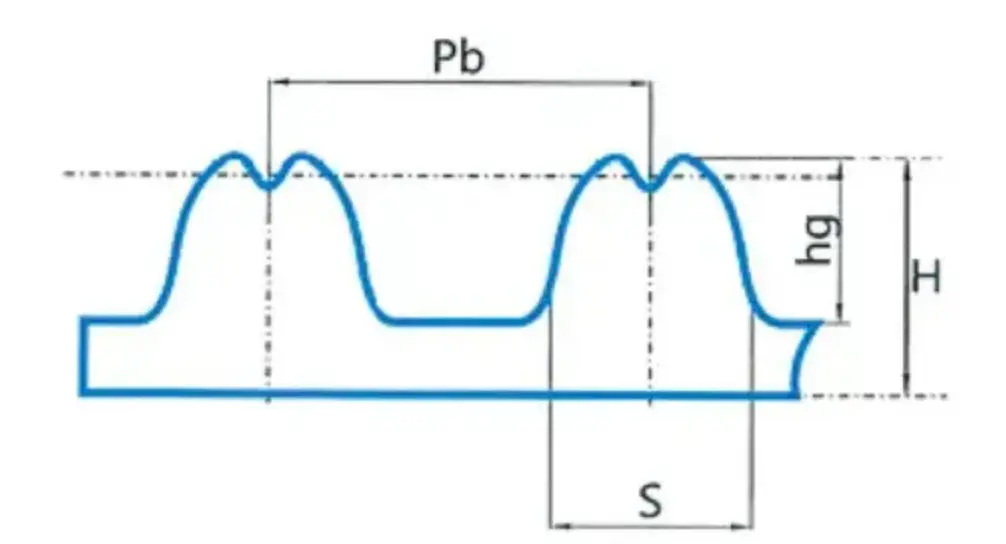

Parabolic Synchronous Belt

|

TYPE |

Pitch |

Bottom tooth thickness |

Tooth height |

Belt thickness |

Teeth number range |

Pitch length |

|

Pb |

S |

hg |

H |

|||

|

P2M |

2 |

1.30 |

0.73 |

1.30 |

56~612 |

112.00~1224.00 |

|

P3M |

3 |

1.95 |

1.09 |

2.10 |

30~621 |

90.00~1863.00 |

|

P5M |

5 |

3.25 |

1.81 |

3.60 |

36~400 |

180.00~2000.00 |

|

P8M |

8 |

5.20 |

2.90 |

5.50 |

40~550 |

320.00~4400.00 |

|

P14M |

14 |

9.50 |

6.00 |

10.00 |

69~327 |

966.00~4578.00 |

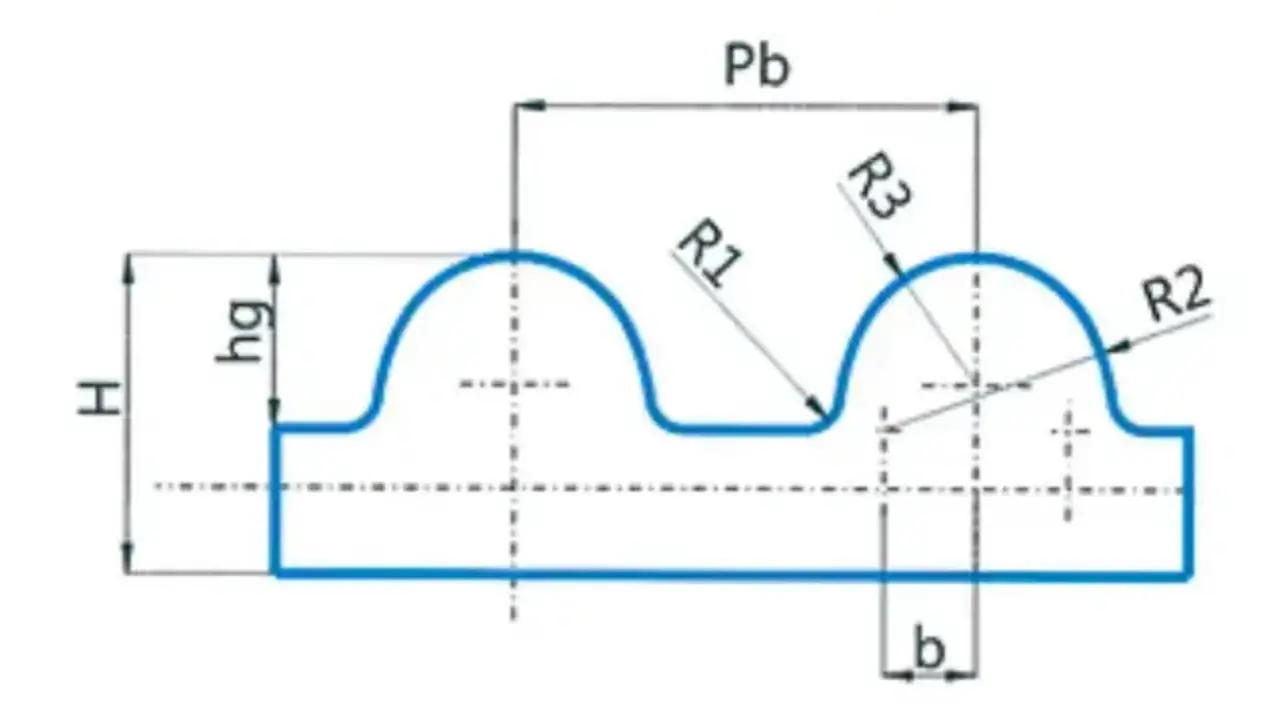

G,Y-toothed Synchronous Belt

|

TYPE |

Pitch |

Tooth height |

Fillet |

Fillet radius |

Top arc |

Belt thickness |

Teeth number range |

Pitch length |

|

|

Pb |

hg |

R1 |

R2 |

R3 |

b |

H |

|||

|

G2M |

2 |

0.75 |

0.15 |

1.00 |

0.555 |

0.75 |

1.38 |

56~612 |

112.00~1224.00 |

|

G3M |

3 |

1.14 |

0.25 |

1.52 |

0.85 |

1.14 |

2.40 |

30~621 |

90.00~1863.00 |

|

G4M |

5 |

1.93 |

0.51 |

2.54 |

1.37 |

1.03 |

3.80 |

36~400 |

180.00~2000.00 |

|

Y8M |

8 |

3.02 |

1.08 |

3.80 |

2.1 |

1.43 |

5.00 |

40~550 |

320.00~4400.00 |

Core application scenarios

Industrial automation

Robotic arm joint transmission | CNC machine tool power transmission | Assembly line synchronous drive

Transportation

Automobile engine timing system | Electric vehicle drive system | Rail transportation equipment

Special industries

Food grade dust-free workshop | Medical equipment precision transmission | Mining machinery corrosion-resistant environment

Why choose us?

1. Strict quality control system

Full process inspection: raw material incoming inspection → production process testing → finished product outgoing inspection

International certification: ISO 9001 quality management system

2. Flexible customization service

Size customization: length and width can be customized freely

Special needs: oil-resistant/conductive/antistatic/flame-retardant coating | color customization

3. Global service network

Fast delivery: China production base | 1000+ spot direct delivery

Technical support: free transmission system technical guidance | 7 to 15 days mass production delivery