5 Ways PU Flat Belts Enhance Your Logistics Efficiency

Customizable Pu Flat Belts play a crucial role in enhancing logistics efficiency. They adapt to various operational demands, making them perfect for tasks likeautomotive assembly and packaging sorting. Their lightweight design reduces equipment strain while maintaining strength, ensuring smooth and efficient material handling across different environments.

Key Takeaways

- Customizable PU flat belts adapt to specific operational needs, enhancing efficiency in various logistics applications.

- Durable PU flat belts resist wear and tear, leading to fewer replacements and reduced maintenance costs, which keeps operations running smoothly.

- Using PU flat belts can improve workflow efficiency by increasing run rates and reducing jams, ultimately boosting productivity in logistics.

Customization Options for PU Flat Belts

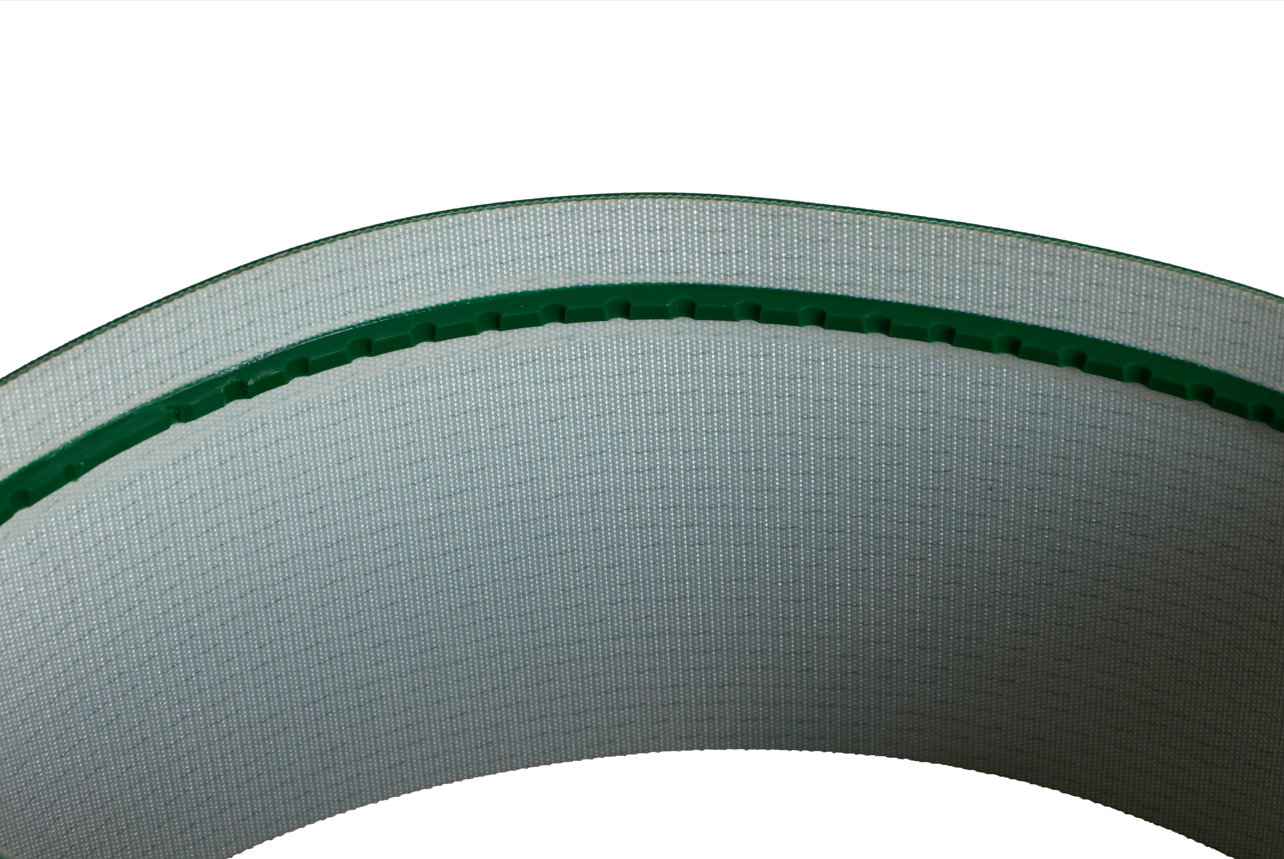

Customization plays a vital role in the effectiveness of PU flat belts in logistics. These belts can be tailored to meet specific needs, ensuring they perform optimally in various applications. Here are some key customization options:

- Welded Profiles: Users can choose from numerous designs to fit their unique applications. This flexibility allows for better integration into existing systems.

- Backing Materials: With over 30 different backing materials available, businesses can select the right one for their environment. This choice enhances durability and performance.

- Machining Options: Companies can opt for grinding, punching, or slitting to achieve precise specifications. This level of detail ensures that the belts fit perfectly in their intended applications.

Additionally, specific industries benefit from unique features. For instance, in food processing, custom coatings like antimicrobial or FDA-approved TPU belts ensure safety. In automotive manufacturing, belts with enhanced grip or abrasion resistance provide precision handling.

These customization options not only improve the functionality of PU flat belts but also contribute to overall logistics efficiency. By selecting the right features, businesses can optimize their operations and reduce downtime.

Durability and Reliability of PU Flat Belts

When it comes to logistics, durability and reliability are key. PU flat belts stand out in these areas, making them a smart choice for businesses. These belts are designed to handle high loads and resist wear, which means they last longer than traditional rubber belts. This durability translates into fewer replacements and less downtime, keeping operations running smoothly.

Here are some properties that highlight the strength of PU flat belts:

| Property | Description |

|---|---|

| High Durability | Designed to withstand high loads and resist wear, ensuring a longer lifespan compared to traditional rubber belts. |

| Temperature Resistance | Can operate effectively in a wide range of temperatures, suitable for both hot and cold environments. |

| Low Stretch | Minimal elongation under load, maintaining shape and performance over time. |

| Chemical Resistance | Resistant to oils, solvents, and other chemicals, ideal for harsh environments. |

In heavy-duty applications, PU flat belts excel. They provide increased uptime and reduced maintenance, making them perfect for continuous use in logistics facilities. Their design minimizes wear and tear, which is essential in demanding environments.

Moreover, PU flat belts maintain consistent performance under various load conditions. This reliability is crucial for high-speed operations, where any hiccup can lead to delays. With their exceptional quality, these belts ensure smooth movement and optimize overall operation.

By choosing PU flat belts, businesses can enhance their logistics efficiency through improved durability and reliability.

Cost Efficiency with PU Flat Belts

Cost efficiency is a significant advantage of using PU flat belts in logistics. These belts not only reduce operational costs but also enhance overall productivity. By investing in PU flat belts, businesses can enjoy long-term savings and improved performance.

One of the main ways PU flat belts save money is through their durability. They resist wear and tear, which means they last longer than traditional belts. This durability leads to fewer replacements, directly lowering maintenance costs. Here are some key points:

- PU conveyor belts have high wear resistance, allowing them to withstand the rigors of daily operations.

- The extended service life of these belts reduces the need for frequent replacements.

- Easy cleaning of PU belts minimizes downtime, allowing for more efficient logistics operations.

Additionally, PU flat belts contribute to energy efficiency. They can reduce energy consumption by up to 15%. This reduction not only supports sustainability goals but also aligns with federal energy-saving initiatives.

| Benefit | Description |

|---|---|

| Energy Efficiency | Conveyor systems using PU flat belts contribute to environmental sustainability and long-term cost savings. |

When evaluating the total cost of ownership, businesses find that higher upfront investments in PU flat belts lead to lower long-term expenses. This includes savings from maintenance, downtime, and replacement costs.

Versatility of PU Flat Belts in Applications

PU flat belts showcase remarkable versatility across various logistics applications. Their adaptability makes them suitable for different environments and tasks, enhancing overall efficiency. Here are some key areas where these belts excel:

- Compressors: They transport components in machinery, ensuring smooth operations.

- Conveyors: Essential for moving goods in assembly lines, PU flat belts streamline processes.

- Machine Tools: These belts help operate various industrial tools effectively.

- Industrial Equipment: They facilitate the movement of parts and finished goods throughout facilities.

PU flat belts adapt seamlessly to different types of logistics equipment. They find extensive use in industries like food, medicine, electronics, and logistics due to their eco-friendly materials and superior performance. Their design with tangential drives leads to energy savings, optimizing systems for various operational conditions.

Additionally, PU flat belts offer several benefits:

- They adapt to steep angle conveying, solving issues of material sliding.

- They resist wear and corrosion, making them suitable for handling ores and chemicals.

- They produce low noise, making them ideal for sensitive environments like food processing.

In packaging and sorting logistics, PU flat belts enhance stability and reliability. They improve efficiency and product quality in the packaging industry, while in sorting applications, they provide smooth operation and accurate transmission. This versatility makes PU flat belts a valuable asset in multi-functional logistics environments.

Improved Workflow with PU Flat Belts

PU flat belts significantly improve workflow efficiency in logistics operations. Their design and features contribute to smoother processes, allowing businesses to operate more effectively. Here are some key benefits:

- Hygiene & Cleanability: PU flat belts come as a single piece, which means no seams where germs can hide. This design enhances cleanliness and reduces downtime for cleaning.

- Durability & Maintenance Efficiency: These belts resist wear and tear from various substances. Their longevity minimizes maintenance needs, contributing to operational efficiency.

- Operational Efficiency & Scalability: Customizable options allow businesses to tailor solutions to their specific needs. This adaptability improves workflow efficiency across different logistics operations.

The impact of PU flat belts on error rates is also noteworthy. They can increase run rates by 10–15% and reduce jams and misfeeds by up to 30%. This improvement leads to extended maintenance intervals, allowing teams to focus on other critical tasks.

| Metric | Improvement |

|---|---|

| Run rate | 10–15% increase |

| Jams and misfeeds | Up to 30% reduction |

| Maintenance intervals | Extended duration |

Several case studies illustrate the benefits of PU flat belts in logistics. For instance, a major e-commerce warehouse improved sorting accuracy to 99.8% with a high-speed conveyor sorting system. This enhancement significantly reduced mis-shipments, showcasing how PU flat belts can transform operations.

| Case Study | Application | Benefit |

|---|---|---|

| High-Speed Sorting at a Distribution Hub | Installation of a high-speed conveyor sorting system in a major e-commerce warehouse. | Improved sorting accuracy to 99.8%, significantly reducing mis-shipments. |

| Distribution Warehouses | Automated sorting and distribution of goods, enhancing order fulfillment processes. | Increases sorting accuracy and reduces delivery times, improving customer satisfaction. |

| Pharmaceutical Manufacturing | Handling sensitive pharmaceutical products through controlled environments to maintain quality and compliance. | Conveyors can be designed to meet strict hygiene and environmental standards, essential in the pharmaceutical industry. |

By integrating PU flat belts into logistics operations, businesses can achieve improved workflows, leading to greater efficiency and productivity.

Customizable PU flat belts bring many advantages that boost logistics efficiency. They offer tailored designs that fit specific needs, ensuring high transmission efficiency and low noise operation. Their lightweight design reduces equipment strain while maintaining strength. Plus, they comply with environmental standards, making them a smart choice for sustainable logistics.

- High Transmission Efficiency

- Low Noise Operation

- Lightweight Design

- Flexibility in Adaptation

- Compliance with Environmental Standards

By integrating these belts, businesses can streamline operations and enhance productivity.

FAQ

What are PU flat belts made of?

PU flat belts consist of polyurethane, a lightweight and durable material that offers excellent wear resistance.

How do PU flat belts improve logistics efficiency?

PU flat belts enhance logistics efficiency through customization, durability, cost savings, versatility, and improved workflows.

Can PU flat belts be used in food processing?

Yes, PU flat belts can be customized with antimicrobial coatings, making them suitable for food processing applications.