Why More OEMs Are Sourcing Rubber Timing Belts from Manufacturers?

Your current sourcing methods for Rubber Timing Belts likely incur unnecessary expenses. Indirect procurement often masks significant financial drains and operational inefficiencies. Directmanufacturer sourcing offers OEMs a clear path to substantial cost reduction and performance enhancement for every rubber timing belt.

Key Takeaways

- Buying rubber timing belts directly from the maker saves money. It removes extra costs from middlemen.

- Direct buying means you get custom-made belts. These belts work better and last longer for your machines.

- Working with the maker makes your supply chain stronger. It helps you get parts on time and improves product quality.

Uncovering the Hidden Costs in Your Rubber Timing Belts Supply Chain

OEMs often overlook hidden costs in their supply chain. These costs can significantly impact your bottom line. They come from intermediaries, generic parts, long lead times, and quality issues. Understanding these hidden expenses helps you make smarter sourcing decisions.

The Markup Burden from Intermediaries

When you buy through distributors or brokers, you pay more. These middlemen add their own profit margins. This means your company pays a higher price than the actual manufacturing cost. This extra money does not add value to the product itself. You might not even know the true factory price. This hidden markup directly affects your budget. It eats into your potential savings.

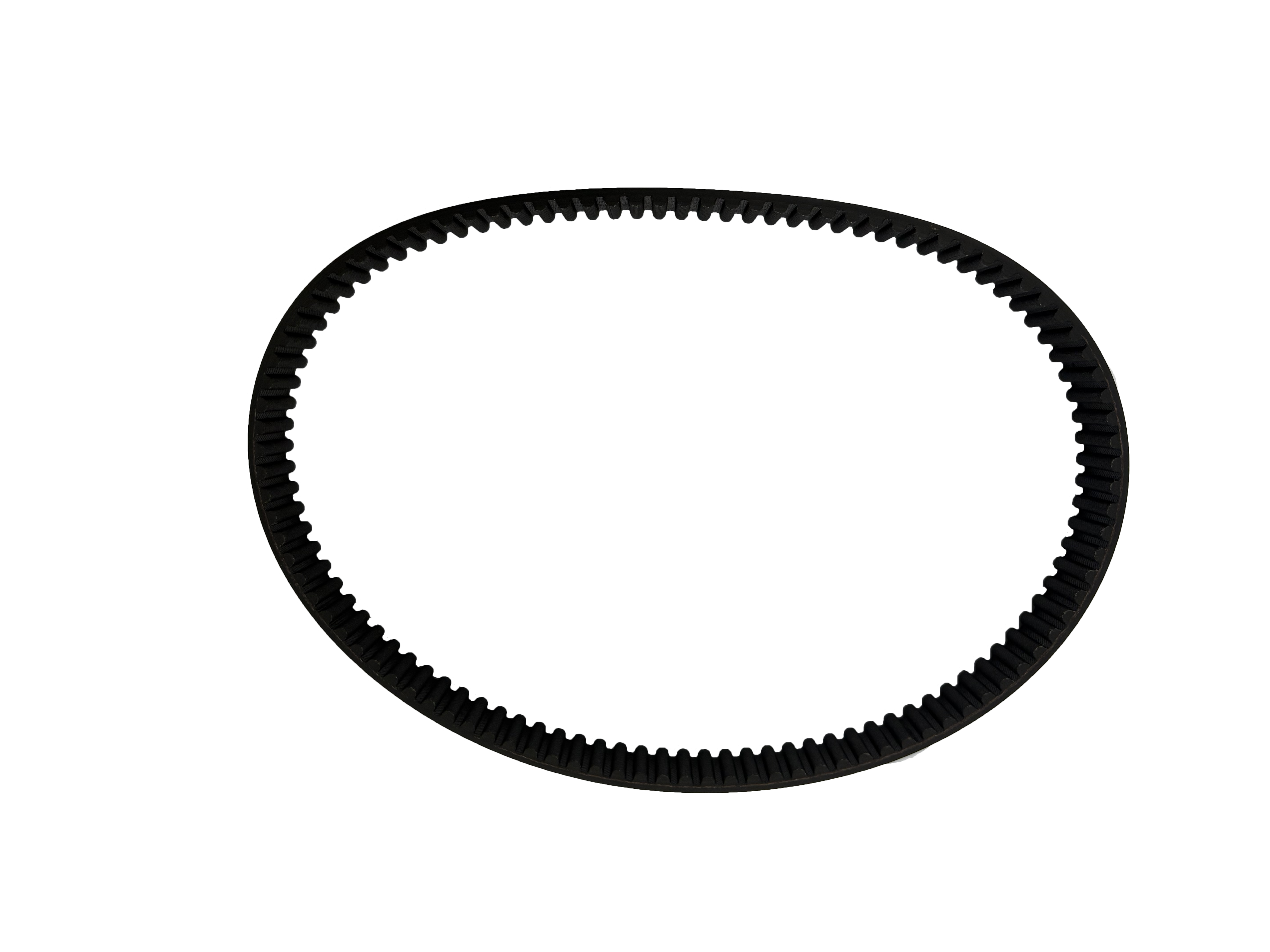

Compromised Performance with Generic Rubber Timing Belts

Generic belts are often "one-size-fits-all" solutions. They might not perfectly match your specific application needs. This can lead to problems. You might see suboptimal performance, reduced efficiency, or a shorter lifespan for your equipment. Generic belts may not handle specific loads, speeds, or environmental conditions well. This means your machines do not run at their best. Custom-engineered solutions, however, fit perfectly. They ensure your equipment operates at peak performance.

Financial Strain from Extended Lead Times and Inventory

Intermediaries can make your supply chain longer. Longer lead times force your company to hold more inventory. Holding inventory costs money. You pay for storage, insurance, and face the risk of parts becoming old or useless. Unexpected delays can also stop your production. This leads to more costs. It also impacts your cash flow. A longer supply chain means less flexibility and higher financial risk for your operations.

The True Cost of Quality Inconsistencies and Failures

Inconsistent quality often leads to belt failures. These failures cost much more than just replacing the belt. Imagine your assembly line stops. This causes significant production delays. You miss your targets. Your maintenance costs go up. You pay more for new parts, labor, and emergency services. A sudden belt failure can also damage other parts in your system. This means bigger repairs or even needing new equipment. Even small belt problems reduce how well your operations run. This affects the overall output and quality of your products. In some cases, belt failures can even create safety risks for people using the machinery. For your finished products, belt failures can lead to warranty claims. Customers become unhappy. You might even face costly product recalls. These costs are far greater than the initial price of the Rubber Timing Belts.

Direct Sourcing: Optimizing Your Investment in Rubber Timing Belts

Direct sourcing offers OEMs a clear path to better products and a more efficient supply chain. It means buying straight from the manufacturer. This approach helps you save money, get superior components, and build a stronger operation.

Achieving True Factory Pricing

When OEMs buy directly, they cut out the middleman. Distributors and brokers add their own profit margins. These markups increase the final price. Direct sourcing means OEMs pay the actual factory cost. This makes pricing clear and honest. It leads to big savings. OEMs can then invest these savings elsewhere.

Custom Engineering for Superior Rubber Timing Belts

Generic belts often do not fit perfectly. Direct sourcing allows custom engineering. Manufacturers design Rubber Timing Belts for specific applications. They choose the best materials. They select the right tooth profiles and sizes. This ensures optimal performance. It also increases durability. Custom solutions mean equipment runs at its peak.

Streamlined Logistics and Reduced Inventory Holding

Direct sourcing shortens the supply chain. Manufacturers ship products straight to the OEM. This reduces lead times. OEMs do not need to keep large amounts of inventory. They save money on storage. They also reduce the risk of old or useless parts. A shorter supply chain makes operations more flexible.

Assured Quality and Manufacturing Consistency

Working directly with a manufacturer ensures consistent quality. OEMs can set clear quality standards. They can monitor the production process. This reduces defects and failures. It builds trust in the components. High-quality parts mean reliable products for customers.

Strategic Advantages Beyond Savings for OEM Rubber Timing Belts

Direct sourcing offers OEMs much more than just lower prices. It brings strategic benefits that significantly boost your products, operations, and market standing. These advantages help you build better products and a stronger business.

Elevating Product Performance and Durability

When you work directly with manufacturers, you get components designed for your exact needs. They create parts that fit perfectly. This means your equipment runs smoother and more efficiently. High-quality Rubber Timing Belts prevent unexpected breakdowns. Your final products become more reliable and last longer. This directly improves the performance and durability of what you sell.

Fostering Innovation Through Direct Collaboration

Direct communication with manufacturers opens doors for innovation. You can share your specific challenges and ideas. Engineers can then develop custom solutions just for you. This direct collaboration speeds up product development. It helps you integrate new technologies faster. You can stay ahead of your competitors by bringing unique, high-performing products to market.

Building Resilient Supply Chains for Critical Components

A direct relationship with your manufacturer makes your supply chain much stronger. You get reliable delivery schedules and avoid unnecessary delays. This is crucial for critical components. Your production lines stay on track. You also reduce risks from global supply chain disruptions. This stability ensures you always have the parts you need, when you need them.

Strengthening Brand Reputation and Customer Trust

Using high-quality, reliable components directly impacts your brand. When your products perform consistently and last longer, customers notice. Fewer failures mean happier customers. They trust your brand more. This positive experience builds a strong reputation in the market. It encourages repeat business and positive word-of-mouth, which is invaluable for your brand's growth.

OEMs make a critical strategic decision when they transition to direct sourcing for durable Rubber Timing Belts. This move eliminates intermediaries, directly translating to significant cost savings. Direct engagement ensures superior quality, customized solutions, and a more robust supply chain. This approach ultimately enhances product reliability, fosters innovation, and boosts overall market competitiveness.

FAQ

This section answers common questions about direct sourcing rubber timing belts. It highlights how OEMs can achieve cost savings, superior quality, and a more efficient supply chain by working directly with manufacturers.

How does direct sourcing save money for OEMs?

- Direct sourcing cuts out middleman markups. OEMs pay true factory prices. This significantly lowers procurement costs. You save money directly.

Can direct manufacturers customize rubber timing belts for specific needs?

- Yes, manufacturers custom-engineer belts. They design for your exact application. This ensures optimal performance and durability. 🛠️

What are the main benefits of a direct relationship with a manufacturer?

- You get clear communication and technical support. This builds a resilient supply chain. It also ensures consistent quality and faster problem-solving.