Top Pinion Gear Manufacturers in China: Ensuring Quality and Reliability

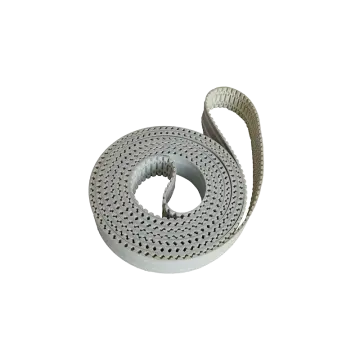

At Nantong Lanpeng Intelligent Machinery Co., Ltd., we specialize in manufacturing high-quality Pinion Gears with a focus on precision and reliability. Our experienced team utilizes advanced technology and top-grade materials to create custom pinion gears tailored to your specific requirements. Whether you need standard sizes or unique designs, we collaborate closely with you to deliver components that meet the highest industry standards. With a commitment to excellence and customer satisfaction, we position ourselves as your preferred partner for all pinion gear solutions. Reach out to us today to discuss your custom manufacturing needs and enhance your operations with our expert solutions.

In-Depth Analysis of Methods Pinion Gear Industry Leaders Ahead of the Curve

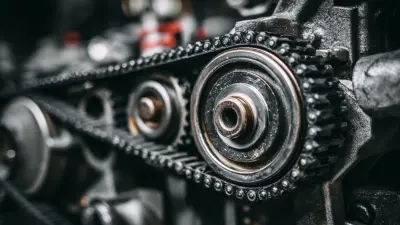

In the rapidly evolving landscape of the manufacturing sector, the pinion gear industry stands out for its crucial role in various applications, from industrial machinery to automotive systems. Understanding the methods employed by industry leaders can provide valuable insights for global procurement professionals seeking to enhance their operations and supply chains. This analysis delves into the strategies that have kept these leaders ahead of the curve, focusing on innovation, quality assurance, and sustainable practices. At the core of successful pinion gear production is advanced manufacturing technology. Leaders in the industry have adopted techniques such as computer numerical control (CNC) machining, which ensures precision and efficiency in gear fabrication. Furthermore, the use of simulation software assists in optimizing designs and predicting performance, ultimately reducing time-to-market. Alongside technological advancements, these companies emphasize stringent quality control measures. Employing internationally recognized standards, they perform rigorous testing throughout the production process to guarantee reliability and durability, which are paramount in maintaining customer trust. Sustainability has also become a focal point for leading manufacturers. By implementing eco-friendly practices and materials, they not only reduce their environmental impact but also appeal to the growing segment of eco-conscious consumers. These leaders are investing in renewable energy sources for their operations and striving towards zero-waste production processes. For global procurement professionals, partnering with such forward-thinking manufacturers can lead to significant benefits, including improved product quality, enhanced operational efficiency, and a stronger alignment with global sustainability goals. In an increasingly competitive market, aligning purchasing strategies with manufacturers that prioritize innovation and sustainability may well be the key to success.

In-Depth Analysis of Methods Pinion Gear Industry Leaders Ahead of the Curve

| Method | Effectiveness (%) | Cost ($) | Industry Application | Implementation Time (months) |

|---|---|---|---|---|

| CNC Machining | 90 | 12000 | Automotive | 6 |

| Additive Manufacturing | 85 | 15000 | Aerospace | 8 |

| Gear Hobbing | 88 | 10000 | Industrial Machinery | 5 |

| Electrochemical Machining | 92 | 18000 | Medical Devices | 12 |

| Precision Casting | 86 | 13000 | Consumer Electronics | 10 |

How Chinese Manufacturers Pinion Gear Industry Giant Market Leader

A

Alexandra Miller

I appreciate the attention to detail in this product. Their customer service is remarkably responsive and friendly.

12 May 2025

J

John Morgan

This product has amazed me with its performance. The after-sales service is equally impressive, showing great expertise.

24 June 2025

Z

Zoe Edwards

This product is fantastic! The team provided quick and insightful answers to all my questions.

30 May 2025

J

Jaxon Hill

This product is incredibly reliable! The after-sales service team exhibited great professionalism in their assistance.

28 June 2025

G

Grace Sanchez

Thrilled with this purchase! The service team was very prompt and incredibly helpful.

21 May 2025

E

Elijah Martinez

A brilliant product! The support staff were attentive and addressed my questions with clarity.

27 May 2025