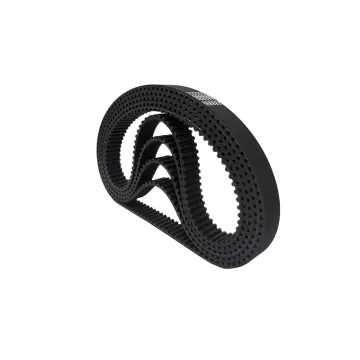

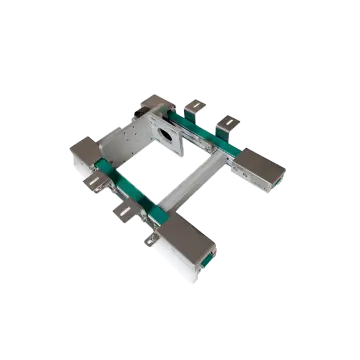

PU connected timing belt | High-precision transmission solution

description1

description2

Product advantages

Using a special splicing process, there is no bulge and no slipping, which completely solves the problem of burrs and easy breakage caused by cutting of traditional synchronous belts, and improves transmission efficiency by 30%.

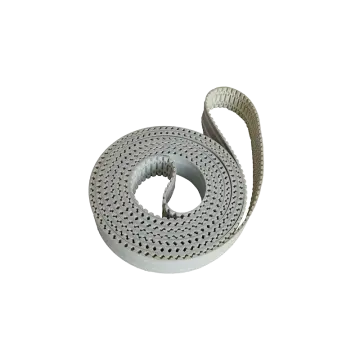

Length can be freely customized

Supports unlimited extension connection (length can be customized, and Belts longer than 1m can be connected), suitable for ultra-long scenes such as large conveyor lines and ring transmission systems, eliminating repeated cutting losses and reducing inventory costs.

Lightweight design, energy-saving and high efficiency

Compared with metal chains, PU connected timing belts are lighter, and can reduce motor load, improve transmission efficiency, and reduce energy consumption. The belts are particularly suitable for high-speed automated production lines and energy-saving equipment.

Flexible customization, one-stop solution

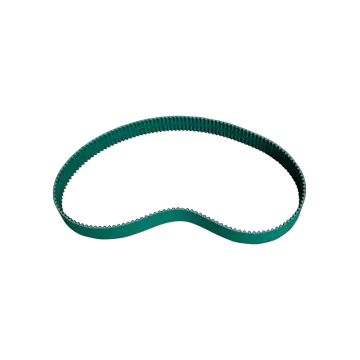

LP belt provides PU connected timing belts with various tooth shapes (HTD/STS/AT/MXL/XL/L/H/XH, etc.), different widths and lengths, and can provide customized services such as special colors, conductive/anti-static treatment according to customer needs to ensure a perfect match for your equipment.

Core technical parameters

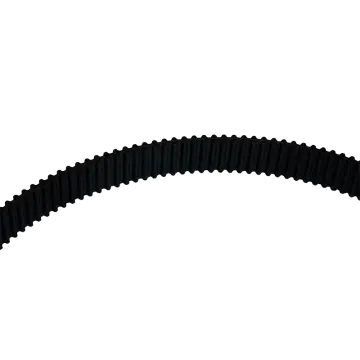

Base material: polyurethane (PU) with steel wire/Kevlar core reinforcement layer (anti-stretching, fatigue-resistant)

Applicable temperature: -30℃ ~ +80℃ (no hardening or breaking in extreme environments)

Surface characteristics: anti-static

Core application scenarios

Extremely long conveying systems: airport baggage sorting lines, mine conveyor belts, automated warehousing and logistics

Ring transmission equipment: printing machines, textile machinery, photovoltaic panel cleaning robots

Emergency maintenance replacement: Replace the traditional closed synchronous belt that needs to be replaced as a whole, saving 80% of maintenance costs.

Advantages of PU/polyurethane welded synchronous belt

Indicators: LP PU connected synchronous belt

Ultra-long transmission requirements: √Seamless splicing, single belt length up to 100 meters or longer

Adaptability to special environments: √PU oil-resistant/low-temperature-resistant/UV-resistant

Matching for niche equipment: √48-hour quick feedback, Customization

Why choose us?

Technical support: Provide professional technical team 1 to 1 selection guidance.

Quick response: 24-hour remote fault diagnosis to ensure timely resolution of customer problems.