010203

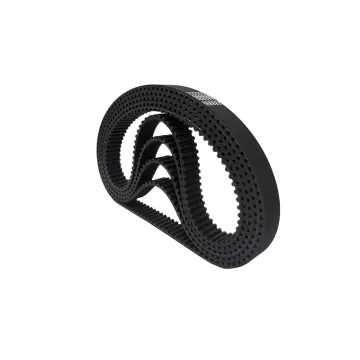

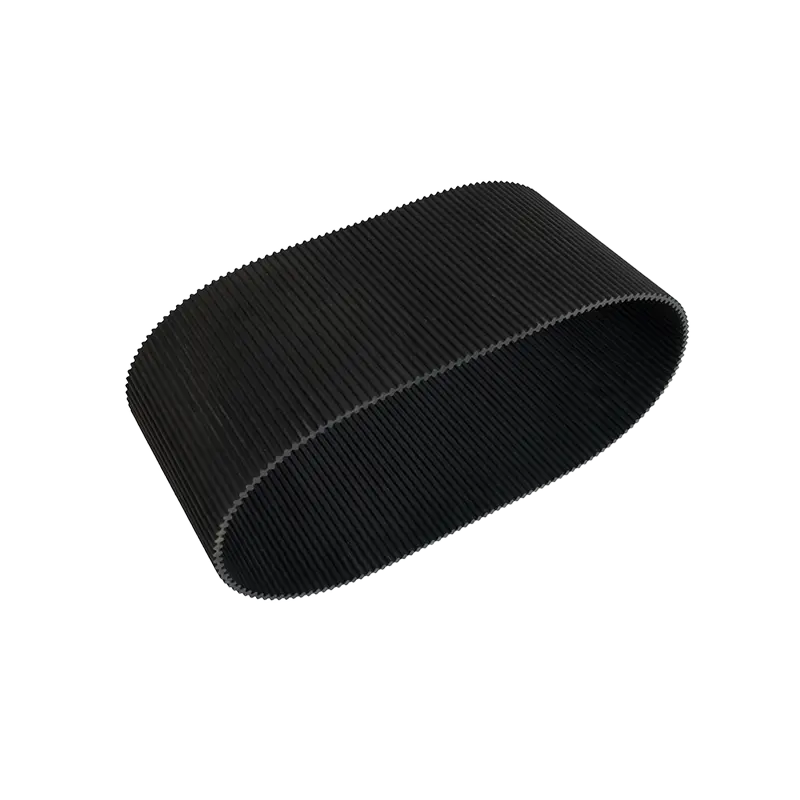

Rubber double-sided synchronous belt | Double-sided transmission, space saving | High strength and wear resistance

description1

description2

Product Description

1. The pitch and tooth shape of the double-sided toothed synchronous belt are produced according to international standards.

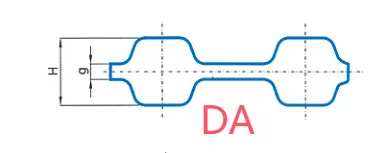

2. The double-sided toothed synchronous belt can be divided into two standards according to the distribution of the belt teeth:

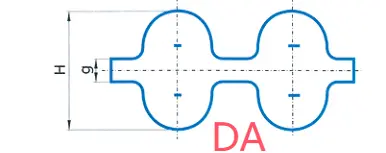

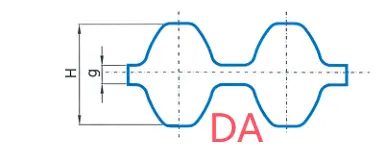

DA type double-sided toothed synchronous belt, the belt teeth on both sides are arranged in parallel:

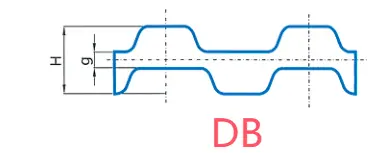

DB type double-sided toothed synchronous belt, the belt teeth on both sides are arranged in staggered positions.

2. The double-sided toothed synchronous belt can be divided into two standards according to the distribution of the belt teeth:

DA type double-sided toothed synchronous belt, the belt teeth on both sides are arranged in parallel:

DB type double-sided toothed synchronous belt, the belt teeth on both sides are arranged in staggered positions.

specification

| Type | g | H | Specification code | Pitch length | Teeth No. |

| D-XL | 0.508 | 3.05 | 158XL~1020XL | 401.32~2590.8 | 79~510 |

| D-L | 0.762 | 4.58 | 217L~1148L | 552.45~2914.65 | 58~306 |

| D-H | 1.372 | 5.95 | 220H-11900H | 558.80~4826.00 | 44~380 |

| D-T5 | 1 | 3.4 | T5×550~T5×2000 | 550.00~2000.00 | 110~400 |

| D-T10 | 2 | 7 | T10×560-T10×4650 | 560.00~4650.00 | 56~465 |

| DA-3M | 0.76 | 3.1 | 402-3M~3000-3M | 402.00~3000.00 | 134~1670 |

| DA-5M | 1.143 | 5.26 | 550-5M~4260-5M | 550.00~4260.00 | 110~852 |

| DA-8M | 1.372 | 7.9 | 552-8M~4520-8M | 552.00~4520.00 | 69~565 |

| DA-14M | 2.8 | 14.84 | 1036-14M~4578-14M | 1036.00~4578.00 | 74~327 |

| DA-S5M | 0.96 | 4.25 | 550-S5M~2800-S5M | 550.00~2800.00 | 110~560 |

| DA-S8M | 1.372 | 7.48 | 560-S8M~4000-S8M | 560.00~4000.00 | 64~500 |

| DA-S14M | 2.8 | 12.36 | 1008-S14M~4508-S14M | 1008.00~4508.00 | 72~322 |

Product advantages

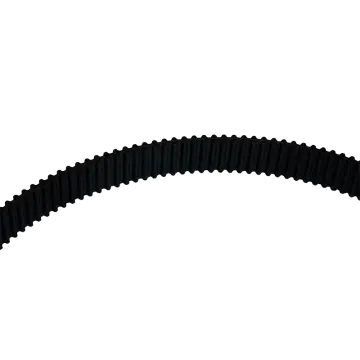

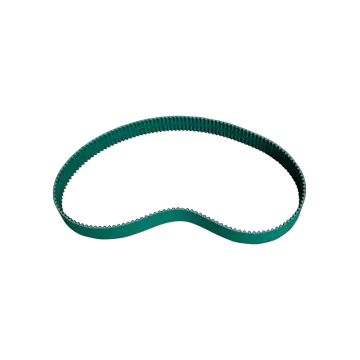

Precise tooth shape on both sides (HTD/STS/XL/L/H/T5/T10 optional), supports synchronous bidirectional transmission, eliminates the need for additional tensioning wheels, and saves more than 30% of equipment space.

The cutting process ensures small pitch error, avoids tooth skipping and slipping, and is compatible with high-precision servo systems.

The cutting process ensures small pitch error, avoids tooth skipping and slipping, and is compatible with high-precision servo systems.

Industrial solutions

| Industry | Typical applications | Pain point solution |

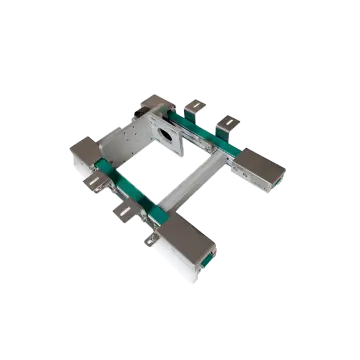

| Industrial robots | Joint bidirectional transmission/robotic arm grasping system | Reduce the number of transmission parts and improve the movement accuracy |

| Packaging machinery | Dual-station synchronous feeding/reciprocating sealing device | Avoid single-sided belt commutation loss and reduce maintenance frequency |

| Medical equipment | Image scanning bed drive/surgical robot power transmission | Dust-free and silent operation |

Why choose us?

1. Strict quality control system

Full process inspection: raw material incoming inspection → production process testing → finished product outgoing inspection

International certification: ISO 9001 quality management system

2. Flexible customization service

Size customization: length and width can be customized freely

3. Global service network

Fast delivery: China production base | 1000+ spot direct delivery

Technical support: free transmission system technical guidance | 7 to 15 days mass production delivery

Full process inspection: raw material incoming inspection → production process testing → finished product outgoing inspection

International certification: ISO 9001 quality management system

2. Flexible customization service

Size customization: length and width can be customized freely

3. Global service network

Fast delivery: China production base | 1000+ spot direct delivery

Technical support: free transmission system technical guidance | 7 to 15 days mass production delivery