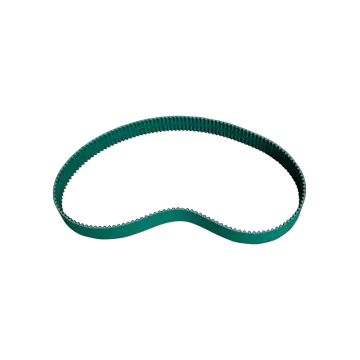

Custom Welded Timing Belts from Top Manufacturers & Exporters for Every Application

As a leading supplier of high-quality Welded Timing Belts, we understand the essential role precision plays in your machinery. Our products are designed for superior durability and performance, making them ideal for your manufacturing requirements. Based in China, we take pride in being a prominent exporter, equipped with a state-of-the-art factory capable of fulfilling high-volume demands. Count on our reliable timing belts to boost productivity and minimize downtime. By choosing our Welded Timing Belts, you benefit from superior quality and competitive pricing that helps maintain your budget. At Nantong Lanpeng Intelligent Machinery Co., Ltd., customer satisfaction is our top priority, ensuring we meet your specifications with professionalism and efficiency. Partner with us for exceptional quality and service that set us apart as a premium manufacturer.10 Essential Tips For Welded Timing Belt Manufacturer Exceeds Industry Benchmarks

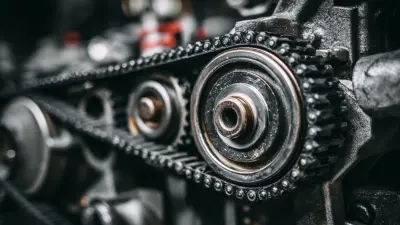

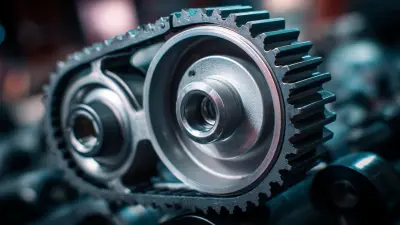

In the competitive landscape of industrial manufacturing, welded timing belts have become a critical component for enhancing the efficiency and reliability of machinery. For manufacturers seeking to exceed industry benchmarks, focusing on quality, durability, and performance is indispensable. Here are ten essential tips that can help your manufacturing process elevate its standards and deliver superior products to global buyers. First, ensure that you utilize high-quality raw materials. The choice of material significantly impacts the longevity and performance of welded timing belts. Prioritize sourcing from reputable suppliers who can provide durable, resilient materials that meet international quality standards. Second, investing in advanced manufacturing technologies can streamline production processes, enhance precision, and reduce wastage, leading to improved efficiency and cost-effectiveness. Moreover, maintaining a rigorous quality control system is essential. Implementing comprehensive testing procedures at different production stages can help identify defects early, ensuring that only the highest quality products reach the market. Engaging in continuous research and development will also keep your offerings aligned with the latest industry trends and innovations, allowing you to adapt to changing customer demands swiftly. By focusing on quality, technology, and innovation, your manufacturing capabilities can not only meet but exceed industry benchmarks, establishing your brand as a preferred choice for global procurement.

10 Essential Tips For Welded Timing Belt Manufacturer Exceeds Industry Benchmarks

| Tip Number | Tip Description | Expected Outcome | Industry Benchmark |

|---|---|---|---|

| 1 | Utilize advanced material technology for durability | Increased product lifespan | Average lifespan increase of 20% |

| 2 | Implement strict quality control measures | Reduced defect rates | Industry defect rate under 2% |

| 3 | Invest in automation for production efficiency | Lower production costs | Cost reduction by 15% |

| 4 | Optimize design for better performance | Enhanced operational efficiency | Performance improvement by 25% |

| 5 | Conduct regular training programs for staff | Higher employee competency | Competency improvement score by 30% |

| 6 | Focus on customer feedback for product enhancement | Better customer satisfaction rates | Customer satisfaction rate above 90% |

| 7 | Maintain robust supply chain management | Minimized supply disruptions | Supply chain disruption rate under 5% |

| 8 | Research and development for innovative solutions | Staying ahead of market trends | New product launches increase 40% |

| 9 | Sustainability initiatives in production | Reduced environmental impact | CO2 emissions reduction by 30% |

| 10 | Develop partnerships with key industry players | Broadened market reach | Increased market share by 15% |

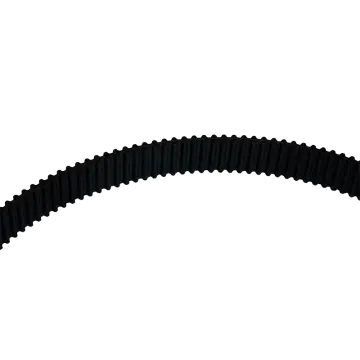

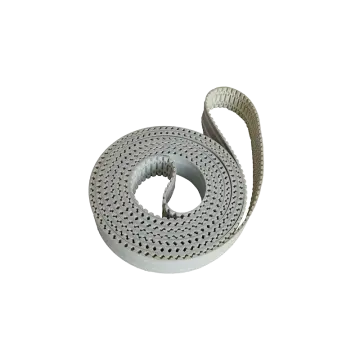

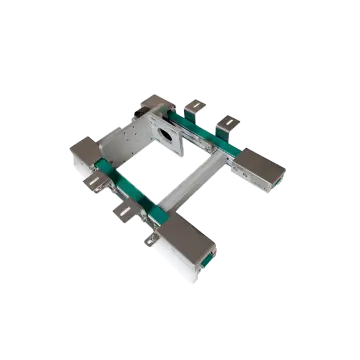

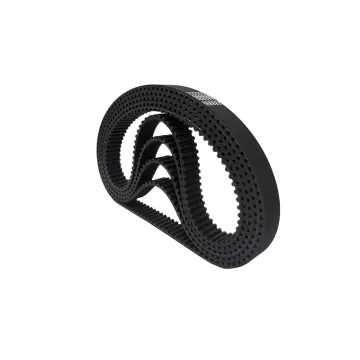

China Top Welded Timing Belt Manufacturer Products

M

Michael Thompson

The quality of the product exceeded my expectations. The after-sales service was prompt and the representative was exceptionally knowledgeable.

09 June 2025

D

Daniel Wright

This product delivers outstanding performance. The service team is impressive, really knows their stuff, and is eager to help.

16 June 2025

S

Sofia Rivera

The product has been fantastic so far. The after-sales service provided thorough answers to my questions.

17 May 2025

S

Scarlett Flores

Absolutely love this product! The after-sales team handled my queries brilliantly, reflecting their expertise.

13 June 2025

G

Grace Sanchez

Thrilled with this purchase! The service team was very prompt and incredibly helpful.

21 May 2025

N

Nina Greene

Outstanding product quality! The support team was fantastic in resolving my issue quickly and professionally.

14 June 2025